HP Jet Fusion 3D Printing Shorten Time to Market – Part 4

Scaling to Production in Rapid Prototyping This is the final segment in our Rapid Prototyping series and here we will talk about scaling to production. When creating a new product, there are often two sets of designs: One set is for 3D printing prototypes while the other is for producing the part. However, most designers only think in terms of the latter. “When you’re developing a product, at each moment of the design, it is a final part,” said Gabriel Boutin, CEO of Syncro Innovation, an industrial design firm in Quebec, Canada, and the founder of Kupol, a new company that designs and produces bike helmets. Kupol designed some of its earliest prototypes of bike helmets using HP Multi Jet Fusion technology, and now it has ramped up to produce them on an HP Jet Fusion 4200 Printer in partnership with Sculpteo, a 3D printing service bureau that owns the machine. Boutin explained that not only has HP 3D Printing saved him time to market, but it also has allowed him to be more creative. “When you don’t have to think in two different ways—for prototyping and production—and can just focus on one thing, you can allow for more creativity,” Boutin said. “With [...]

Sand Casting

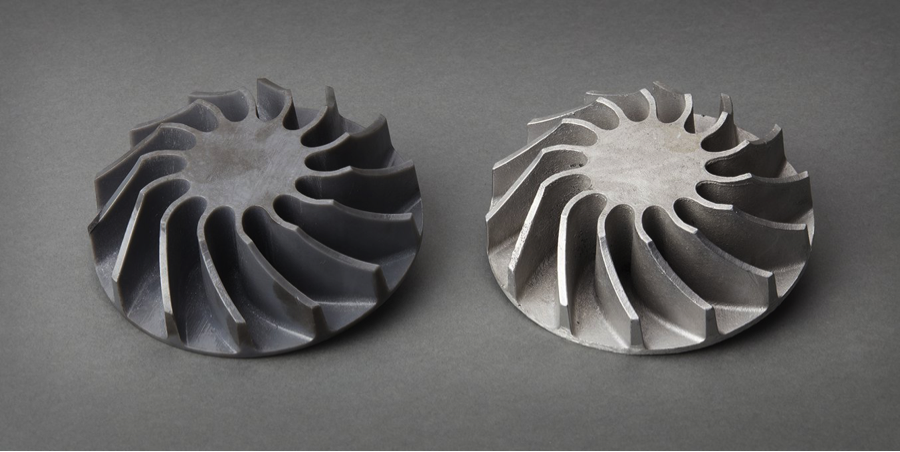

This article is a reprint from the Formlabs blog. In the last segment of this casting basics, we will discuss sand casting. In the sand casting process, a foundry worker fills containers known as mold boxes or flasks with a mixture of sand and binder, then packs sand around the pattern. The pattern is removed to leave a negative impression of the pattern behind, and molten metal is poured into the cavity. An open-faced mold may be used for parts with features on a single side. Parts with features on multiple surfaces require closed cavity molds, with upper and lower mold boxes, referred to as cope and drag. Grey Resin printed pattern and finished aluminum casting from an open-faced sand mold. In a closed mold, metal travels through a gating system before reaching the part cavity. This gating system is carefully designed to minimize structural and aesthetic imperfections resulting from improper metal flow. Closed cavity sand molds sometimes make use of suspended cores to create internal cavities in the finished castings, as in the case of engine blocks or pump housings. We hope you enjoyed our 4-part series on casting.

HP Jet Fusion 3D Printing Shortens Time to Market – Part 3

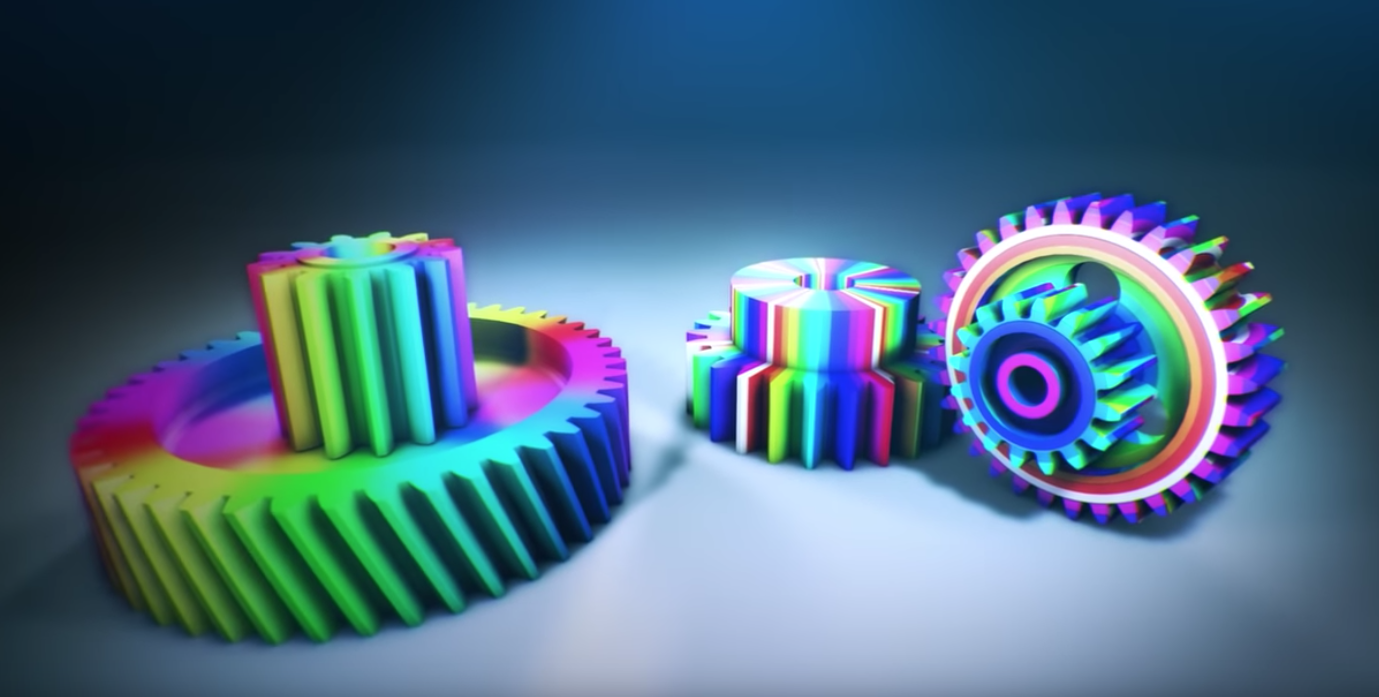

Last week we discussed the “value of functional prototypes” in rapid prototyping and today we are going to continue with a discussion about the color capabilities of the HP Jet Fusion technology. Color Capabilities of HP Jet Fusion Technology There are many ways to improve the value of a prototype, but one that is often overlooked is the addition of color. With the HP Jet Fusion 580/380 Color 3D Printers, it is now possible to print fully functional, color 3D parts. Adding color to prototypes is one way to test final part colors, but there are other ways to use color in prototypes. “One application we see is in aerospace,” said Ken Burns, the Technical Sales Director for Forecast 3D, a custom manufacturing and 3D printing service bureau. “Color can be used to differentiate the functional and the placeholder parts in an assembly. Red would be a great indicator for this since it draws attention.” Color also can be used to easily label or differentiate segments of a prototype, for example, in a part where fluids flow through different channels. Even simple text labels like a prototype revision number or the name of the designer who created the part can be incredibly valuable [...]

Indirect Investment Casting

This article is a reprint from the Formlabs blog. So far we’ve covered some metal casting basics, as well as direct investment casting in our blog series on casting. Today we are moving to indirect investment casting. The process of making patterns from molds or tooling is referred to as indirect investment casting because it requires creating molds for producing the patterns in addition to final investment molds. Rigid molds for wax (often referred to as tools) are commonly fabricated by machining aluminum or steel. Machined metal molds cost thousands of dollars to produce and take weeks of machining and polishing work before first shots can be run and pattern parts evaluated within a casting process. By directly printing tooling, engineers and designers can reduce the time between concept and first tests from weeks to a matter of days. A 3D printed mold in Clear Resin for wax injection. Molds for producing wax patterns can be printed with High Temp Resin. For optimal surface finish of molded parts, treat the interior surfaces of the mold by sanding and polishing for a smooth look, or bead blasting if a uniform matte look is desired. To ensure the final cast parts are dimensionally [...]

HP Jet Fusion 3D Printing Shortens Time to Market – Part 2

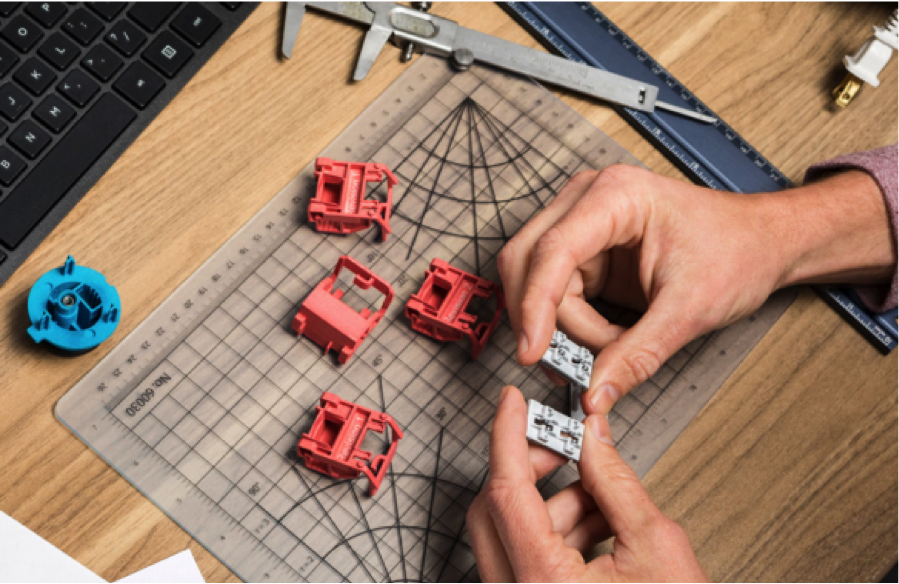

The value of functional prototypes Picking up where we left off on our article about “How HP Jet Fusion 3D Printing customers shorten their time to market” today we will discuss the value of functional prototypes. In addition to print speed, the material properties of parts from HP Jet Fusion 3D Printing Solutions are ideal for prototyping and enable customers to make decisions about their final parts. HP Multi Jet Fusion technology allows for the creation of highly isotropic parts, or parts that have similar properties when measured in the X, Y, and Z dimensions. “Isotropy is important so that the designer does not need to take the time to communicate extra design intents, like where strength and dimensional accuracy are most important in the part,” says Boyes. “In other additive processes, it is important to orient the part such that the strength is not needed between layers. In terms of strength, parts produced with HP MJF technology are not as sensitive to orientation, so less time is spent from engineering to getting the parts in hand that can be used in production.” Furthermore, HP prints with engineering-grade thermoplastic and has the capability to print with high dimensional accuracy. This enables customers to [...]

Direct Investment Casting

Last week we covered some metal casting basics and today we are going to pick up where we left off. Today we will talk about direct investment casting. The direct investment casting process moves straight from creating a pattern to surrounding that pattern with investment material. Since the wax injection method of creating a pattern requires multiple steps, it is considered indirect. Direct investment casting is best for short runs of parts or initial testing of a part concept, as each printed part will require some finishing steps. Direct investment casting is also a good choice for large parts or parts with thick cross-sections that may be more difficult to mold successfully in wax due to warping and shrinkage. Direct investment casting is valuable for producing parts with geometries that are too complex to be molded or for parts with extensive undercuts and fine surface texture details, where molding is possible but carries high tooling costs. Cast parts from SLA patterns printed on a Form 2 in Clear Resin. Traditionally, patterns for direct investment casting are carved by hand or machined if the part is a one-off or expected to be only a handful of units. With the advent of 3D [...]