HP Launches HP 5200 Series 3D Printers

HP just launched a new line of Jet Fusion 3D printers, the HP 5200 series. HP’s latest machines target volume production, with accuracy and repeatability likened to injection molding. The company also released a new flexible TPU for Jet Fusion, confirmed new industrial alliances, and introduced its Digital Manufacturing Network. This new 5200 series is part of a natural progression at the company. The 500/300 series targeted functional prototyping and the 4200 is aimed at short runs and production. The new 5200 series is HP’s 3D printer for volume production. Volume production, as defined by HP, is production runs in the thousands of parts. Depending on size and complexity, this number can reach tens of thousands or even hundreds of thousands of parts. The main driver of this productivity is the upgraded power of lamps inside 5200 3D printers. More power means the printhead can do more with one single pass and fuse materials with much higher temperature. The series has also been released alongside a cooling unit, which automatically removes a finished print bed and replaces it with a fresh one to minimize downtime. This is such late-breaking news that we don't have these products listed on our website yet. Please stay [...]

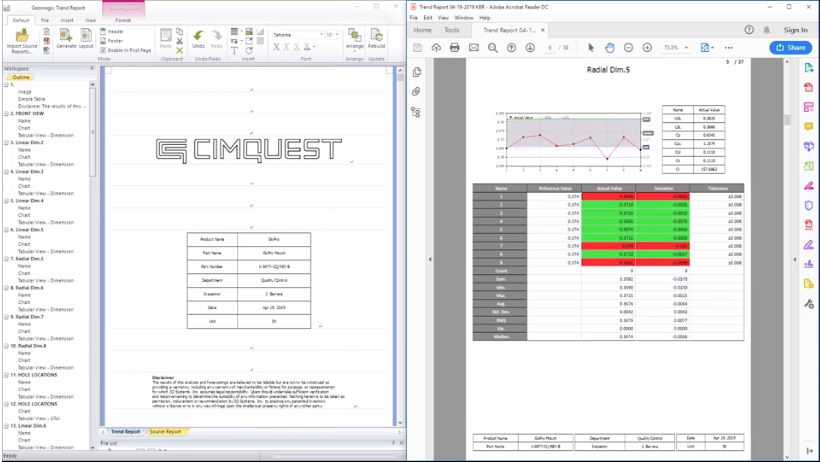

Trend Analysis in Geomagic Control X

Today we will discuss how to analyze various trends of inspection results. The non-contact inspection world is ever growing. More and more companies are using metrology grade scanners to inspect their product. This allows them to utilize the scans and check geometric dimensions and tolerances, extract 3D deviation color maps, and quickly generate full-color 2D and 3D PDFs. But what if you wanted to take this even further and analyze trends based on your inspection results? This is exactly what Geomagic Control X software is able to do. Shown above is a GoPro mount that we designed in-house, and the goal is to track the length, width, and a few other critical dimensions of the manufactured part. At this point in time, we have already scanned and processed them in Control X and produced an XML file for each. From here, we are ready to open the Trend Report application. After selecting the source reports, choose the entities that you want track or report, whether it’s a linear dimension, geometric tolerance, and so forth. Statistical data is then generated for each entity. For example, if you analyze the trend for a linear dimension, the first chart will show the upper and lower control [...]

Desktop Metal Studio+ Current Materials

Desktop Metal's Bound Metal Deposition technology brings metal 3D printing into the office environment, making low-cost prototyping of metal parts achievable as well as user-friendly and cost-effective. The Studio printer extrudes rods that have metal powder bound within wax and plastic to form the parts. The binders in these parts are then removed through a two-step process of debinding and sintering similar to metal injection molding; also known as MIM. Desktop Metal's Bound Metal Deposition platform will ultimately have access to a wide range of metals from the MIM industry and there are currently 30 materials in development. The materials currently available are 17-4 & 316 stainless steels: 17-4 stainless is characterized by its combination of strength, hardness, and corrosion resistance. It is ideal for a variety of applications including tooling, molds, and production parts. In its as-sintered state, 17-4's material properties consistently meet industry standards. 316 stainless was just released and is a fully austenitic steel known for its corrosion resistance and performance at both high and low temperatures. It is well-suited for applications involving chemical processing, saltwater environments, and household or industrial fixtures. One great example is a Fuel nozzle by John Zink Hamworthy Combustion, used on steam propulsion boilers on [...]

HP Develops New Digital Textile Printers Using Additive Manufacturing

reprint from https://3dprintingindustry.com The HP STITCH S500 and. Image via HP. HP has launched a portfolio of digital textile printers for fast and precise color-matching. The new products show how additive manufacturing is increasingly used for end-use production. This new range of large-format 2D printers, named the HP Stitch S series, incorporates 3D printed parts. Using additive manufacturing has saved the company an estimated $145,000 in tooling, design prototype modifications and final parts production. The three new printers in the textile range include the HP Stitch S300, the HP Stitch S500, and the HP Stitch S1000. “Décor and fashion application trends, on-demand production and personalization are boosting digital print growth,” said Santi Morera, Head of Graphics Solutions Business at HP. HP Multi Jet fusion technology uses Nylon 12 (PA 12), fusing and detailing agents, to create high precision 3D printed parts with quality surface finishes. This process was utilized for several end-use and prototyped parts for the HP Stitch S Series printers. One of the 3D printed parts includes a sensor pixar. This is located on the flat platform of the printer (platen) and moves the media, detecting the progress of each print job. HP reported savings of approximately $15,000 in [...]

3D Scanning a Porsche GT3

It's not every day you get to perform 3D scanning on a Porsche GT3. We were lucky enough to spend a day last week with one of our customers in the aftermarket industry. In less than one day, we were able to capture the overall geometry of the car and then take scans of individual components, which altogether will be used to validate future aftermarket component designs. Here's a glimpse of some of the action. And here's a little video.

Desktop Metal User Spotlight – Alpha Precision Group

https://cimquesttv.wistia.com/medias/gw4al6zpky?embedType=iframe&videoFoam=true&videoWidth=640 Cimquest is excited to showcase one of our customers, Alpha Precision Group. Since their initial implementation of the Desktop Studio system just 8 months ago, they have created over 200 metal parts (100 of them unique). APG is excited about the value proposition of the technology and share how Bound Metal Deposition has impacted their business objectives through this informative video. Learn about some of the parts they have done thus far and why they are pleased with the results of their Desktop Metal Studio printer!