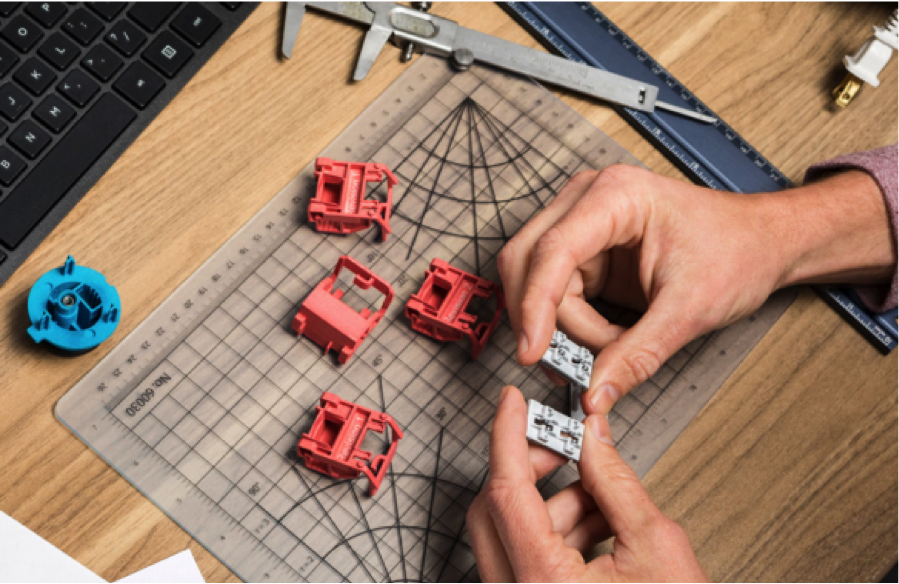

Xpand3D Event Gains Another Sponsor

We just signed on another event sponsor. Thank you to Hurco/Takumi for your support. Hurco Companies, Inc., is based in Indianapolis, Indiana and has 11 divisions worldwide. Hurco has been revolutionizing the manufacturing industry since 1968 with CNC machines that leverage the power of technology to help job shops in high mix/small batch manufacturing be more productive and more profitable. Two brands of CNC machines in the Hurco Companies corporate portfolio are represented at CimQUest: [...]