Import Organic Shapes into CAD – Part 3

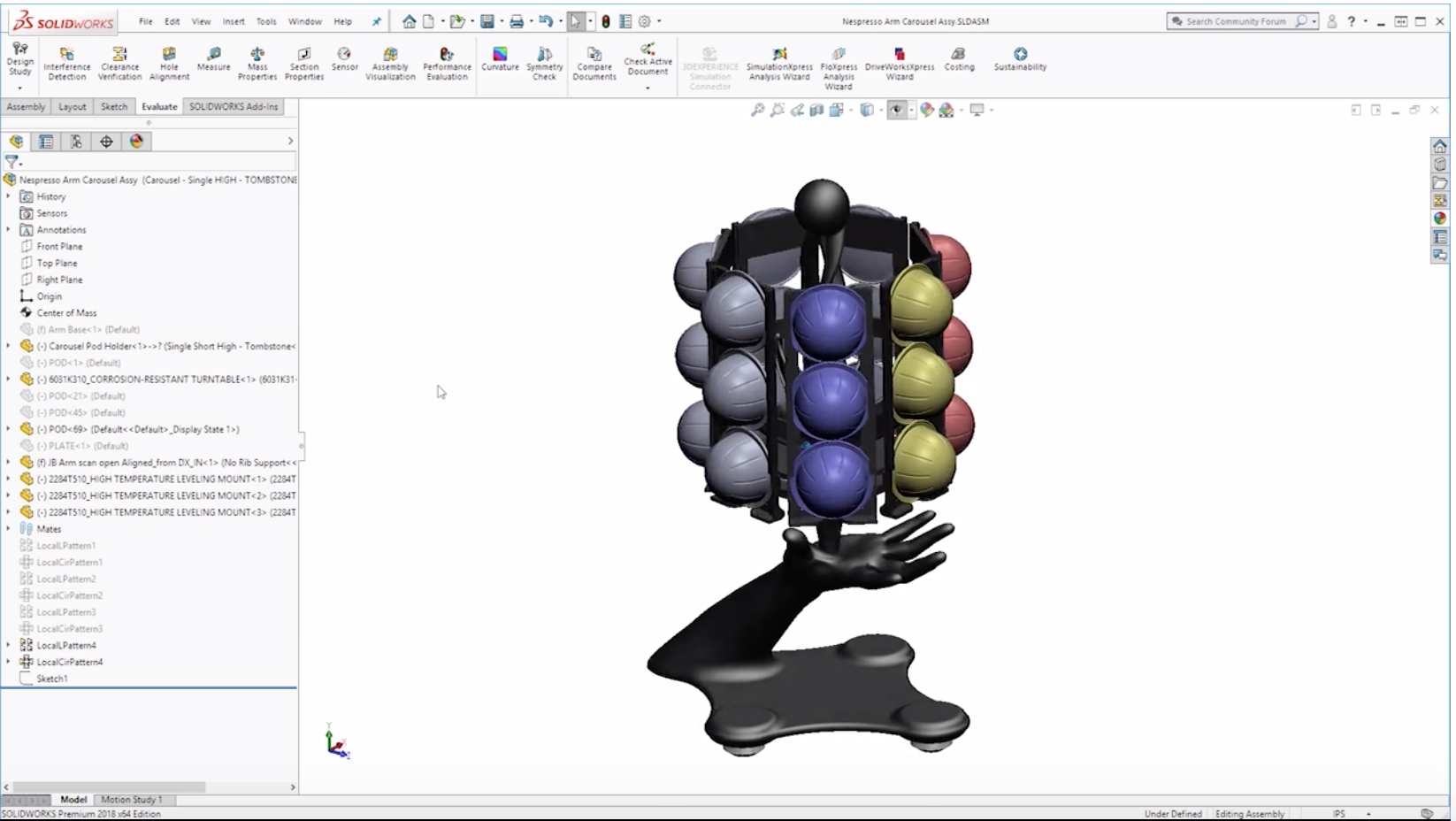

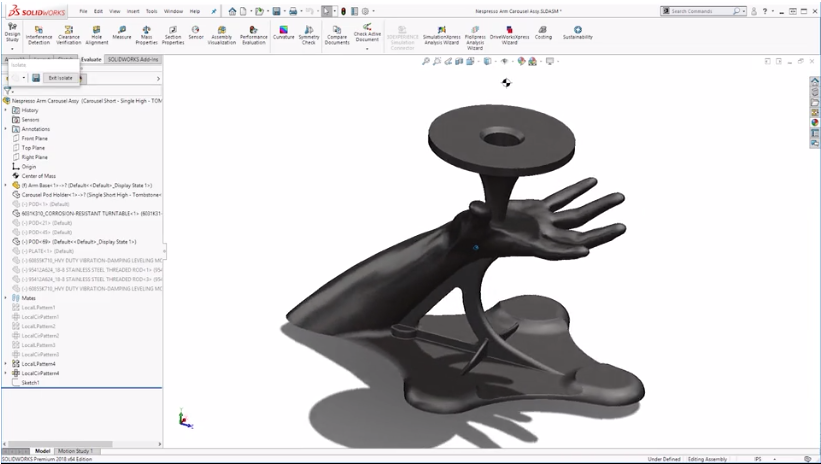

This post is Part 3 of the topic: Leverage and import organic shapes into CAD and today we will introduce you to Generative Design. In previous posts, we briefly discussed the value of having the ability to capture organic shapes for use in CAD design. To illustrate this process, scanned our engineer’s hand and then integrated that scan into CAD in order to design a rotating Nespresso Pod holder. Now, we will finalize the CAD [...]