Leverage and Import Organic Shapes into CAD (Pt. 1)

This article will discuss leveraging organic shapes, and utilizing them in the CAD world. So why is it important to have that ability? In design, there are many situations that arise that may require the utilization of organic or freeform shapes. One example of this is the optional bust cap design on the MDCI perfume bottles. After carefully hand-crafting these, this complex shape needs to be inserted into the final cap design, producing some gorgeous results. To have to model those shapes in CAD would be a bear! Another example of when organic shapes might be required is when you are creating an ergonomic design. Whether you are following the shape of your lower back, your legs, or your hands, that freeform shape needs to be created, then included in the final mechanical design. This was the case of Joe Olson, who in less than a year, created the ErgoJoystick, to replace the typical knobs that cause fatigue due to the fact that they are designed for an upright position. Again, complex shapes, leveraged into CAD. The question is, how do you take complex organic freeform shapes, and bring them into the CAD world where you can complete the design and make it [...]

Rize Receives Two Prestigious Technology Awards

RIZE, the makers of the Rize One 3D printer, has received two prestigious technology awards from industry analysts. RIZE was selected a 2018 IDC Innovator for 3D Printing and they also received The Frost & Sullivan 2018 Award for Best Practices in Technology Innovation – Zero-Emission Polymer Material Additive Manufacturing. Their receipt of these two distinctions results from the dedication of many individuals, including their technical team, their customers, and their partners. We are proud to represent them and enthusiastically acknowledge and celebrate their achievements. For more information on the Rize One 3D printer, please click the button below. More info

We are Growing Our Team

Cimquest is growing and will be looking to hire several more candidates over the next year in the roles of: 3D Printing Application Specialist (Ohio), Marketing/Events (NJ), 3D Printer Sales (NJ/NY), 3D Printing Field Service (MA), 3D Printing Outside Sales (MA), 3D Printing Outside Sales (OH/MI), Inside Sales (NJ), Software/Hardware Maint Sales (NJ) and 3D Printing Outside Sales (VA/MD). We currently have the following position open . . . SERVICE TECHNICIAN (3D PRINTERS) OPPORTUNITY DESCRIPTION: This position is for a technician for our growing line of 3D Printer solutions including HP and Desktop Metal. The technician will be based out of our Branchburg, NJ headquarters but will travel 85% of the time in our territory that spans from Maine down thru Virginia as well as out to the Ohio Valley region. As our printer business continues to grow the travel will become more localized as we add remote technicians to the team to handle the more southern, northern and western regions. Full training will be provided for the technician both internally and by our vendors. Provide 3D Printer installation and training services at customer sites Service 3D Printers Provide professional and customer service oriented telephone support for customers Help with demonstrations of the [...]

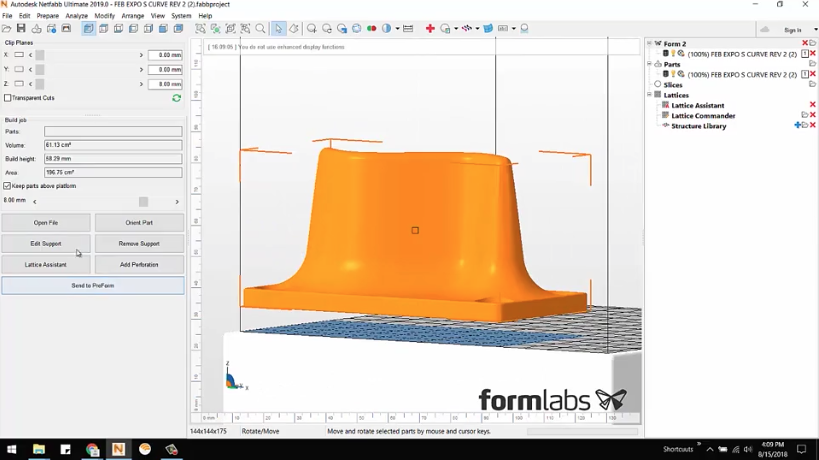

Autodesk Netfabb – Sending a Part to the Form 2 Printer

This blog post will show you how to use Autodesk Netfabb Standard to orient, lattice, add supports, and send a part to your Formlabs Form 2 3D printer. Autodesk Netfabb is Additive Manufacturing software that connects directly to many AM systems. There are three tiers of Netfabb: Standard, Premium, and Ultimate. In order to connect to the Formlabs Form 2 workspace Standard tier is required. When using the latest version, Netfabb 2019 you will be able to drag and drop a file into the program. Since Netfabb has a CAD importer built in, you do not need to purchase any specific file types in order to bring in a native CAD file. A dialogue box will appear with information on the file and, most important, the green check mark that states the file does not have any errors and can be sent to the workspace. When you open the Form 2 workspace you will see the build platform for the Form 2 and the outline of the build volume. After bringing in my part you can orient the part by selecting through the recommendations. Upon accepting the orientation and choosing the Lattice Assistant, it will hollow out the part and add a lattice [...]

New Hudson Facades Saves $50K per Quarter with Rize One 3D Printer

Architectural glass specialist New Hudson Facades (NHF) is reportedly saving up to $50 thousand per quarter with a new, round-the-clock 3D printing facility. The company has installed a Rize One 3D printer at its office in Pennsylvania to produce custom tooling and fixtures for its large-scale projects. According to Andrew Black, Engineering Manager at NHF, “I put Rize One right next to my desk, so I can use it all the time. It’s so easy, anyone can use it.” Miscellaneous Rize 3D printed project tooling at NHF. Photos via Rize Sky’s the limit Founded in 2014, NHF undertakes the installation of custom aluminum and glass façades for skyscrapers. Its most recent projects include the front of three towers in Hudson Yards, New York, including the striking 35 Hudson Yards with a concave feature wall. Facade of 35 Hudson Yards, a project by NHF. Photo via New Hudson Façades On average, each project at NHF relies on the production of between one hundred and two hundred unique fixtures used to help hold aluminum profiles in place, and ensure the perfect fit of the windows. Typically, this tooling would be made using the site’s CNC machines, costing around $200 per part. [...]

CMM Master – Portable Inspection System

Today we are going to talk about a portable CMM called the CMM Master. The CMM Master is based on the Renishaw Equator, and powered by Verisurf’s AUTOMATE software. The working volume is approximately 12” X 12” X 6” up from the plate. It has been volumetrically error mapped with the Verisurf software to an accuracy of +/- .0005î, making it more accurate than the standard Equator. Its single point repeatability is within a couple of tenths! Verisurf's AUTOMATE software, allows you to create complete automated inspection plans. Once this plan is created, you click on the Play button and AUTOMATE takes over. It runs the full inspection plan, collects data for each feature, and at the end of the routine automatically generates a date and time stamped report. The CMM Master is very fast. It has a maximum movement speed of 500 mm/s, or 19.7î in/sec. If you choose to use the probe as a scanner, you input the scan parameters in Verisurf, and the probe scans at a maximum speed of 100 mm/s, almost 4î per sec. At the same time, it can collect up to 1000 points/sec. The CMM Master has built in, user-friendly Calibration Routines that allow you to [...]