True and Full Color 3D Printing

We live in a color world. We see everything in color. Whether you’re a designer, engineer, architect, artist, animator, student, doctor, healthcare provider, entrepreneur or consumer – you live, think and imagine in full, living color. Why 3D print in color? For professionals, most products are designed with the look of the product being paramount – how will it stand out over the others on the shelf? Shape is also very important, but color is one way to make your products stand out over the competition. Color allows you to communicate better within an organization, and color also allows you to communicate better with your clients. For consumers, we want to be able to print gifts and keepsakes, such as 3D photos and statues, in full color, and not be limited to single color objects – in the same way, that we want to be able to 2D print in color. Imagine if you had the capability to see and hold a physical 3D printed model as it would actually appear as a real-life object, just as if you printed a color photo of the object on a 2D printer, but now a full 3D photograph in your hand. Photo-quality 3D objects [...]

HP 3D Printing Open House

Cimquest will be hosting an interactive 3D Printing Open House featuring the HP Multi Jet Fusion Technology. Come take a look under the hood of our new Jet Fusion 4200 and experience the printing process from start to finish. We’ll show you how you can make production quality parts at a greater speed and lower cost per part than other systems. At the event, you will have an opportunity to: Meet HP representatives and discuss the technology and open materials roadmap. See and experience the MJF process live, from start to finish with the Jet Fusion 4200. Learn how the HP 3D Printing Technology saves you time and money compared to other technologies. Cost comparison of running low volume production parts versus injection molding. EVENT DETAILS January 17, 2018 9:00 am - 12:00 pm Cimquest HQ 3434 Rt. 22 West, Suite 130 Branchburg, NJ 08876 Breakfast and lunch will be served, and you'll also get a tour of Cimquest's new CNC Manufacturing Lab and our 3D Printing Showroom. This event is free to attend, but please reserve your spot by clicking on the button below. We hope to see you there! Sign Up!

Reverse Engineering a BMW Speaker

Reverse Engineering has many purposes, one of them being to recreate parts or components that are no longer manufactured. With straight-forward mechanical components, this can be accomplished with a variety of measuring instruments. This task can quickly become more complex though, if the part takes on more of a freeform or ergonomic shape. To serve as an example, the president of our company recently had one of his speaker covers broken. Despite the fact that this is something that can be purchased, we decided to reverse engineer it with all the available tools here at Cimquest. The first step was to scan the part and capture as much as the geometry as possible. This was done with the Creaform HandyScan 700 scanner, which has a resolution of .2 millimeters. Next, we imported the scan into Geomagic Design X. This software allows us to interrogate our scan, and trace the outline of each feature that we need in order to recreate our CAD file. When we’re done, we end up with a fully-featured, editable CAD file that can be exported into a variety of CAD packages. In CAD, you are able leverage these fully editable features to make modifications and optimize your design. The [...]

HP 3D Printing Webinar

HP is offering an informational 3D printing webinar tomorrow afternoon - The Advantages of Designing for MJF Instead of Injection Molding. During this webinar, they will discuss how designing for MJF can optimize costs, free the engineer of constraints imposed by injection molding, and accelerate the development process through delivering production quality parts at the prototype phase and enabling rapid iteration. Attendees will understand how keeping in mind designing for MJF while taking advantage of the freedom of design that 3D printing affords can dramatically affect production costs. This event is tomorrow afternoon so don't delay in registering. Details below. Date December 5th2:00 PM - 3:00 PM Speaker John Briden Senior R&D Manager, HP John Briden is a Stanford Mechanical Engineering graduate who has spent a career developing products at leading consumer electronics companies like Apple and HP Inc. He recently joined HP’s Multi-Jet-Fusion 3D printing group to help usher in the next industrial revolution with 3D printing for production. Register for this event by clicking the button below. Register Here

3D Printing Conceptual Models with Formlabs

3D printing conceptual models is a great way to save time and money early on in the development stage. Engineers can use printers as a sketch pad to build and test out various iterations, and determine necessary adjustments to improve the design. Functional parts take prototyping to the next level, allowing engineers to test models for form and fit and to see how they perform in an assembly. Depending on the application, it is sometimes necessary to combine multiple parts using screws or some other form of fastening. Formlabs has collected various design options for screw threads that can be used with their Tough engineering resin. In the white paper download below, you can learn about all of the options, see the pros and cons of each method, and determine the best fit for your application. Just click the blue bottom below for the PDF download. Download Whitepaper

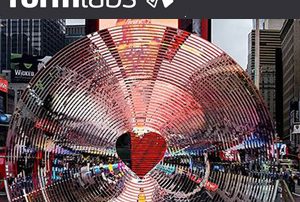

Behind the Design of the World’s Largest Lens

Reprint from www.formlabs.com Today, the world’s largest lens is located in a lighthouse on Oahu, Hawaii. The Fresnel lens at Makapu’u Point, 12 feet tall, 8 feet wide, and painstakingly crafted out of glass, has held the title since 1893. This coming Valentine’s Day, the title will transition to a new lens: a 10-by-12-foot Fresnel lens made of interlocking 3D printed bricks. The installation, Window to the Heart, is a collaboration between Formlabs head of design Marcelo Coelho and design studio Aranda\Lasch, and is the winner of the 2018 Times Square Valentine Heart Design Competition. Previous winners include The Office for Creative Research, Collective-LOK, Stereotank, Young Projects, and Situ Studio. Window to the Heart is designed and 3D printed specifically to distort and capture the image of Times Square, optically bending light—and attention—to a heart-shaped window at its center. Visitors can look through the window or photograph themselves within it, completing the loop between the lens of the eye and the lens of the camera. A Lens that Reflects Culture “Marcelo and I walked around Times Square and noticed that everyone has their camera out, photographing themselves in the light of the media around them. In this sense, Times Square is a symbol [...]