AMUG Announces 2020 Scholarship Winner

photo courtesy of www.tctmagazine.com The Additive Manufacturing Users Group Scholarship Committee has recently named this year's recipients of its two annual scholarship awards. The scholarships, which give one student and one teacher the opportunity to attend the annual additive manufacturing (AM) conference, are designed to recognize educational leaders with a passion for 3D printing technology. We are proud to continue our support for this scholarship that provides the opportunity for highly motivated students to earn the opportunity to attend the Additive Manufacturing User Group (AMUG) conference. The Guy E. Bourdeau Scholarship was founded by Guy’s wife Renee Bourdeau, and is financially supported by Cimquest. This year, congratulations goes to Katherine Schneidau, a mechanical engineering graduate student at the University of Louisville for winning the scholarship. Schneidau's first interaction with AM was through an engineering co-op at the U of L Rapid Prototyping Center where she gained experience with a range of processes and found her passion for the field. Applying her hands-on technical know-how, Schneidau has created new process parameters for both polymers and metals, and in one particular project, developed a flexible recoater blade for use in the EOS M270 and M290 systems. As a graduate student, Schneidau has been actively [...]

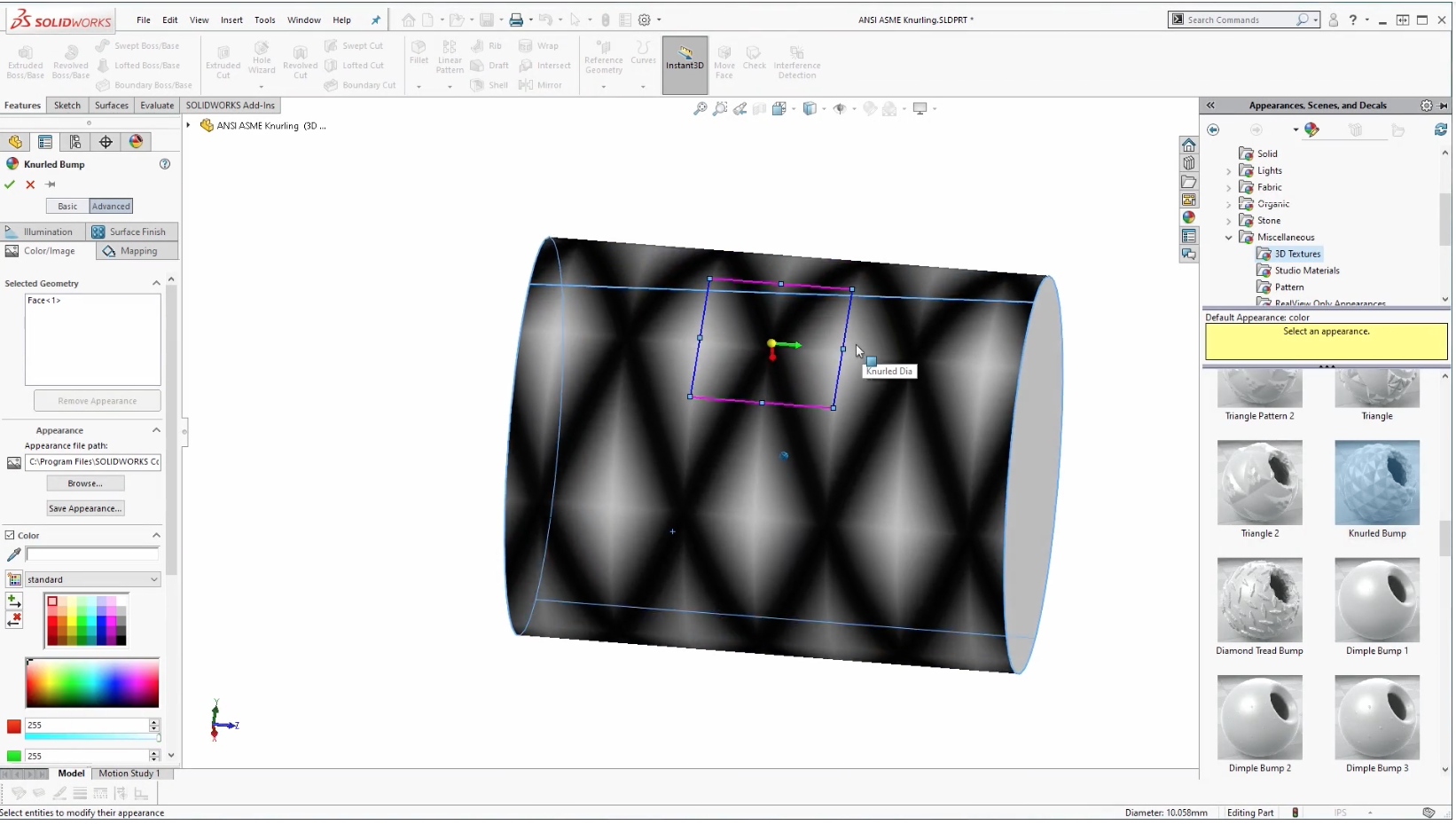

SolidWorks 3D Texture

Have you ever found yourself having to create some type of texturing to your 3D models, whether it be dimples, knurls, bumps like the image below? A straightforward way to accomplish this is to create the planes, sketches and features that will give you that type of shape, then use some type of pattern to complete the 3D texture over the complete surface. Although that works, SolidWorks has come up with a quicker way to accomplish the same task. The tool is called Solidworks 3D Textures, and it works in a two-step process. First, you map a textural appearance to a model using texture mapping functionality. In the mapping tab, you are able to modify the mapping settings, as well as the size and orientation. The second step involves using the 3D Texture tool to define the geometry for the textural appearance and create the 3D texture feature. In the property manager, you are able to define things like Texture Refinement, Texture Offset Distance, and Maximum Element size. Click the green checkmark, and the 3D texture has been created for you! As you can see, SolidWorks continues to give you tools that can quickly and efficiently help you create complex 3D textures, in [...]

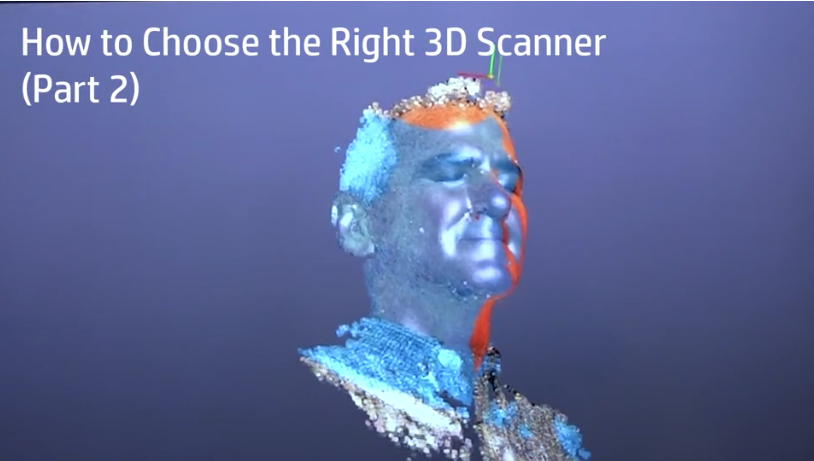

How to Choose the Right 3D Scanner – Part 2

In part one of this “How to Choose the Right 3D Scanner” series we discussed scanning accuracy and resolution. In addition to these attributes, many scanners can also capture what we refer to as texture or color texture. Very often, when scanning a shape, color texture isn't terribly important, unless the scans will be used for 3D color printing, to display on a website, or for use in AR/VR. But in too many cases, color texture is used to hide poor resolution scans. Think of how much detail there is in a human ear. This is a scan of an ear with the texture turned on. To the casual eye, this looks like an excellent scan. The underlying mesh resolution is hidden by the color texture. But watch what happens when we simply turn off the texture. It almost doesn't look like a human ear anymore. With the triangles of the mesh turned on you get a sense as to why this is a very poor resolution mesh. If you consider the mesh file as approximating a shape with triangles, realize how much smaller the triangles would need to be in high curvature areas on the ear in order for this scan to [...]

Metal Goes Mainstream – Thoughts From the Desktop Metal Reseller Conference

Late last month I had the opportunity (along with others from Cimquest) to attend the annual Desktop Metal conference in Jacksonville Florida. Unfortunately, the sunshine state didn't live up to expectations with overcast skies, high winds, and temperatures in the low 50's. Everyone seemed to blame us northerners on dragging the arctic winds with us on our travels. However, despite the cool temperatures, we had a great time gaining a better understanding of the hot new technologies that Desktop Metal is going to and has brought to the market. Sitting through the presentations I had to reflect on the fact that this very young company (just over 4 years old) has and is revolutionizing the world of metal additive manufacturing and beyond (see Fiber below.) Ric Fulop's vision of mainstreaming metal 3D Printing and bringing about a new chapter in additive where the production of metal printed parts can reach a level of simplicity, volume, cost-effectiveness and repeatability never thought possible. In fact, it reminds me of what HP has done to make the production of additive plastic parts competitive to low volume injection molding. Since the first shipments of the office-friendly Studio printer back 2 years ago, the talented team as Desktop [...]

New Cimquest Office Opens in Florida

Cimquest officially opened their new office in Florida on January 23rd. It was well attended by local companies who had the opportunity to see the HP 5200 production system, the Desktop Metal Studio System, and take a tour of the Seaway Plastics facility. Attendees got to meet with the Cimquest expert staff and HP 3D Printing specialists while interacting with real 3D printed parts made from a range of engineering-grade materials. Rob Hassold, CEO of Cimquest attended the Grand Opening and said . . . "It was great to get to spend time with people that are interested in learning about what 3D Printing can do to help launch their business to the next level. I am excited about the next step for Cimquest, opening up a Florida facility and the opportunity to bring HP and Desktop Metal 3D Printing to Florida and the surrounding territory."

Cimquest and Nexa3D Announce Partnership

Cimquest, Inc and Nexa3D Announce Partnership to Enter the Eastern US 3D Printing Market Cimquest, a leading provider of 3D printers, and manufacturing and design products today, announced a partnership with Nexa3D, the maker of ultrafast stereolithography production 3D printers. After an extensive vetting process, this new agreement fills a gap in our product offering to provide a true mass production photocure printer. "When we chose to revamp our 3D printing product line almost two and a half years ago to address the shift in the market from prototyping to production, we knew it was going to take time to identify and test technology that could lead Cimquest and our customers into the next decade,” said Cimquest CEO Rob Hassold. “With the growing success we are having with the HP multi-jet-fusion printers, we knew it was time for us to complement and expand our portfolio with a true mass production photocure printer,” continued Rob. We are excited that after an extensive evaluation of all available options, we concluded that Nexa3D’s new exciting technology is the right solution for our customers." Nexa3D plans to deliver a significant upgrade for tens of thousands of older legacy stereolithography printer users with their flagship printer, the NXE400. [...]