Mastercam 2019 Find Level From Geometry

There is an underutilized feature in Mastercam called Find Level from Geometry, that can be found inside of the Levels Manager. This is a useful tool when you look at part files that have lots of different levels, each with their own geometry, whether it is wireframe, solids, or surface models on the screen. Usually what users do is turn all their levels off and then one by one, turn each one back on to see if they can find which level has their geometry. This tool though allows you to quickly find what level your geometry is on so you can keep making changes to the right level and organize everything quickly and easily. First, let’s look at a typical part file inside of Mastercam. As you can see in the example below, in the Levels Manager there are 12 levels, each with at least 9 entities on a level. When importing assembly models or other solid models in Mastercam, they will typically assign themselves to a new level with the solid body name as the level name if the configuration is set up correctly. Usually, looking at these level names isn’t really clear what level contains which solid body and wireframe. [...]

Moldmaking with 3D Prints

Moldmaking with desktop 3D printing allows engineers and designers to get much more functionality from their 3D printer, beyond prototyping alone. Moldmaking opens a world of production materials and provides the ability to produce short-run batches and test mold designs prior to committing to expensive tooling. Download an educational White Paper from Formlabs to learn about mold making strategies including injection molding, thermoforming and casting elastomers. Just complete the form below and you will gain access to the White Paper.

Import Organic Shapes into CAD – Part 3

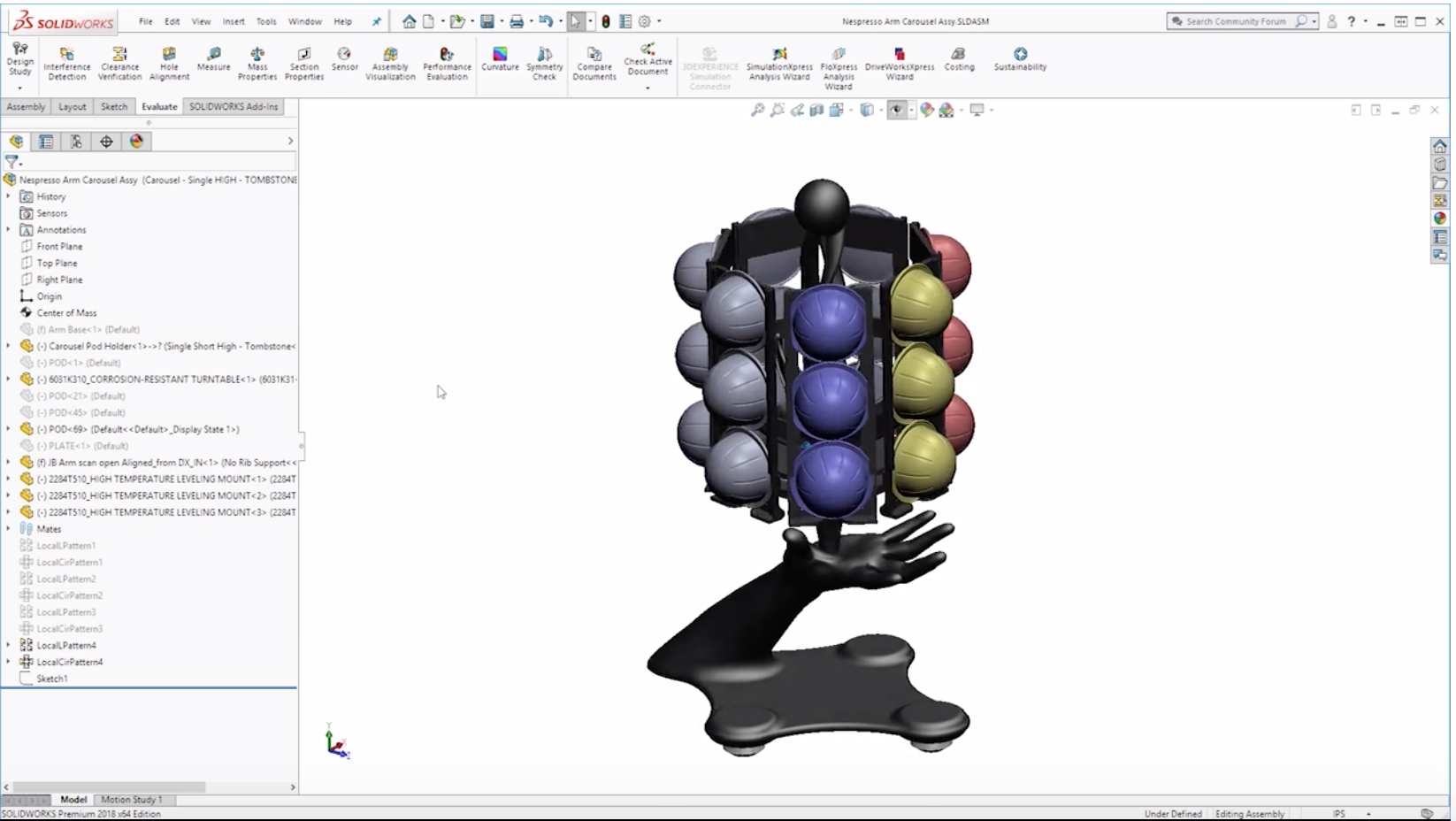

This post is Part 3 of the topic: Leverage and import organic shapes into CAD and today we will introduce you to Generative Design. In previous posts, we briefly discussed the value of having the ability to capture organic shapes for use in CAD design. To illustrate this process, scanned our engineer’s hand and then integrated that scan into CAD in order to design a rotating Nespresso Pod holder. Now, we will finalize the CAD design phase by using Fusion's Generative Design, to assist us during the model creation process. By now, the Nespresso pod holder is almost complete. The base integrates the hand and forearm and we have a carousel that sits and rotates on a turntable about the center of the palm. Now we need to determine how the turntable will connect to the pod holders. Traditionally, we would make our initial attempt and create a shape that we think would be structurally sound. We would then run that shape through FEA; make modifications, and repeat this cycle to ensure that we don't over design the part. A short cut to this iterative cycle is to use Fusion's Generative Design. In essence, the software generates a design or shape, based on [...]

Special Offer from Rize and SOLIDWORKS

Accelerate Innovation with Unified Design and 3D Printing RIZE and Dassault Systèmes recently made three key announcements: RIZE Receives Frost & Sullivan Award for Best Practices in Technology Innovation for Zero-Emissions Polymer Additive Manufacturing RIZE Announces $15M in Series B Funding from Innospark Ventures, Sparta Group LLC, Converge and Dassault Systèmes RIZE Announces Strategic Partnership with Dassault Systèmes to Drive Sustainable Innovation and Faster Time to Market SOLIDWORKS is the world leader in driving innovation. Design for Additive Manufacturing requires a rich set of applications from generative methodologies, material science and advanced simulation available in the SOLIDWORKS portfolio. RIZE solutions integrated with SOLIDWORKS will accelerate product innovation for design, manufacturing, tooling and service. RIZE 3D printers, including XRIZETM that lets you print functional full-color and carbon fiber parts, enables engineers to produce intelligent parts for design, manufacturing and service. RIZE provides a safe and easy additive manufacturing experience that will accelerate innovation among all users in offices, factories, schools and distribution environments. RIZE parts provide digitally connected and augmented experiences for traceability, built-in trust and IP controls. With zero harmful emissions, using only safe, recyclable materials and with minimal pre- and post-processing. SPECIAL OFFER Effective February 11, 2019, every RIZE 3D printer purchase [...]

Desktop Metal Introduces 316L Stainless Steel

Desktop Metal recently added 316L stainless steel to their list of printable metals on the Studio System. Characterized by its corrosion resistance and performance at both high and low temperatures, 316L is a fully austenitic stainless steel ideal for harsh environments. Expert metallurgy is at the core of the Studio System, which was built to simplify even the most challenging aspects of metal fabrication—including easy material changes in under a minute. The introduction of 316L creates new opportunities for designers and engineers to prototype and produce parts for particularly demanding environments such as marine applications, chemical processing, and medical devices. About the Material 316L is a molybdenum-bearing, fully-austenitic stainless steel. It’s known for its excellent corrosion resistance—for example, it's resistance to pitting corrosion—and mechanical properties at both high and low temperatures. 316L is a common material used in a wide variety of applications, including: Chemical and petrochemical processing Food processing Laboratory equipment Medical devices Marine Jewelry Power generation Petroleum refining Water treatment Pulp and paper manufacturing Download the Data Sheet

Leverage and Import Organic Shapes into CAD – Part 3

https://cimquesttv.wistia.com/medias/im6j9p3ygj?embedType=iframe&videoFoam=true&videoWidth=640 In this third episode, we finalize the CAD design phase by using Autodesk Fusion's Generative Design. This can be a great tool to use when you want to create an optimal design that meets engineering criteria.