XRIZE 3D Printer Special Promotion

Rize just announced their newest product, the XRIZE. The new XRIZE™ 3D printer will enable users to manufacture functional polymer and composite parts in full color. Like RIZE's first product, RIZE™ ONE, the experience of using the XRIZE 3D printer is as easy and safe as an office 2D printer. XRIZE will enable full-color prototypes for FEA and stress analysis, tooling with safety instructions, consumer products, package design, GIS mapping, anatomical parts for patient/clinician communication, pre-surgical planning and parts for marketing and the entertainment industry. XRIZE will be available for shipping in H1 2019 and will be priced at USD $55,000. And the best news . . . For a limited time, until December 27, 2018, if you pre-order XRIZE, you will receive a RIZE ONE included in the price. That's 2 printers for the price of 1. Please click the button below for more details. More Details

Introducing XRIZE 3D Printer

XRIZE is the world's first desktop Industrial Additive Manufacturing solution for creating vibrant, full-color functional parts with minimal post-processing. Until now, users had to produce non-functional color parts or implement very expensive solutions, making tradeoffs between color, strength, and price. These tradeoffs have limited the expansion of additive manufacturing to users across the enterprise and inhibited true innovation. Moreover, companies had to purchase separate 3D printers to achieve varying capabilities, including office use, full color, end-use, and production parts and the ability to use carbon fiber and other materials. For the first time in the industry, XRIZE enables users to manufacture functional polymer and composite parts in full color. And since RIZE’s intelligent and innovative solutions focus on the user as much as the machine, XRIZE is easy to use, safe and enables markup to provide much-desired IP security, traceability, and branding. Like RIZE’s first product, RIZE™ ONE, the experience of using the XRIZE 3D printer is as easy and safe as an office 2D printer. Providing a safe, clean process, minimal pre- and post-processing and minimal material management, users throughout the enterprise, from engineering to marketing to the manufacturing floor, can use XRIZE to easily manufacture full-color prototypes for FEA and stress analysis, tooling with [...]

Customer Spotlight – Miguel Horn sculptor

Miguel Horn, a sculptor and visual artist in Philadelphia recently used 3D scanning for one of his projects. He has worked with the Philadelphia Academy of Fine Arts, and other local art institutions and he tries to use as many digital production methods as he can. He feels that this allows him to speed up fabrication, as well as use a variety of different new materials. In 2015 Miguel was approached to develop a concept for a public art opportunity. Philadelphia has a program where 1% of public funding for development in the city construction and architecture must be allocated towards art. His project was to create an architectural feature for a bridge that features a traditional esthetic with contemporary production methods. Miguel turned to Cimquest for our scanning services and, with our help, was able to perform a high-resolution scan in significantly less time than he could have done with his desktop scanner. He shaved off 6-8 weeks of production time! Miguel will use the data to reproduce the sculpture and have it installed as a city attraction. Please click the button below to view a video of the full story. View Video

Making Fluid Tight Parts with HP 3D Printing

This article will discuss the fluid tightness of HP Multi Jet Fusion parts and show some real-life examples. HP MJF parts have been proven to be watertight without any additional post-processing, therefore parts can be used to have liquids or gases flow through designed channels. There are several variables that can be looked at to determine what a part can withstand. Using these variables, HP has conducted multiple tests with HP’s 3D High Reusability PA 12, tests that prove spherical shapes will hold higher pressures. Additionally, the design freedom of 3D printing helps to improve the efficiency of these components. For example, ducts can be unified and optimized for better product space due to geometries not possible with other technologies. There is also a greater level of customization possible among assemblies. Along with the structural strength of HP MJF parts, PA12 has a high chemical resistance, making it ideal for interaction with many fluids. This chart shows some of the fluids that have been tested. Now, let's take a look at several examples of MJF parts that are in use today: First, inside the JF 4200 there are over 60 MJF parts and one of these is this air duct. This is several [...]

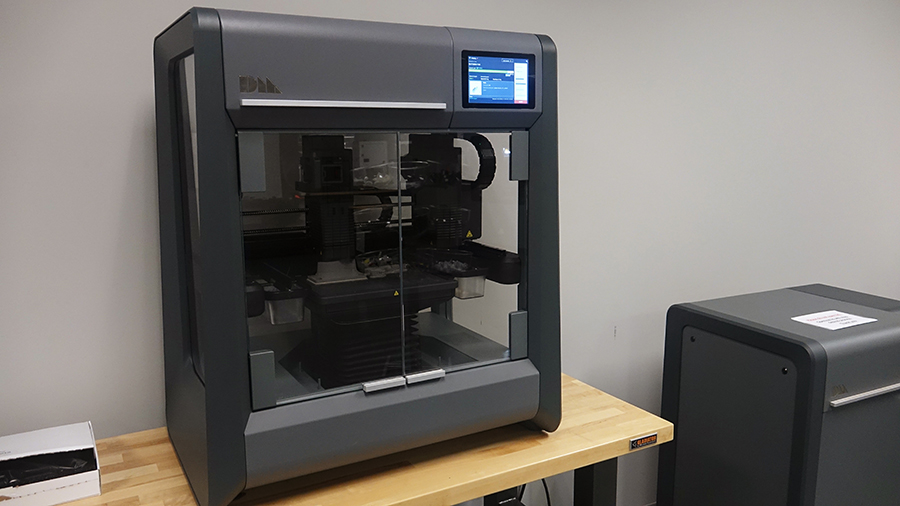

Desktop Metal Studio Machine Added to Our 3D Printing Arsenal

We are very excited to announce the arrival of our Desktop Metal Studio Machine and Debinder. Upon adding metal 3D Printing to our arsenal of Advanced Manufacturing Technology solutions, we fully intend to leverage our decades of experience supporting manufacturing in the region via conventional tooling processes such as CNC Machining. Our ability to process metal parts will be invaluable as we work closely with our customers to target and develop key applications for Desktop Metal's Bound Metal Deposition Technology. For example, in cases where parts need to hold tighter tolerances then the "as sintered" specifications, or a better surface finish might be required to produce injection mold tooling such as mold inserts, Cimquest can utilize our 3 and 5 axis Takumi & Hurco CNC Mills for post-machining. An end-to-end solution The Desktop Metal Studio System is a three-part solution that automates metal 3D printing. Tightly integrated through Desktop Metal’s cloud-based software, it delivers a seamless workflow for printing complex metal parts in-house—from digital file to sintered part. Unlike laser-based systems that selectively melt metal powder, the printer extrudes bound metal rods—similar to how an FDM printer works. This eliminates the safety requirements often associated with metal 3D printing while enabling new features [...]

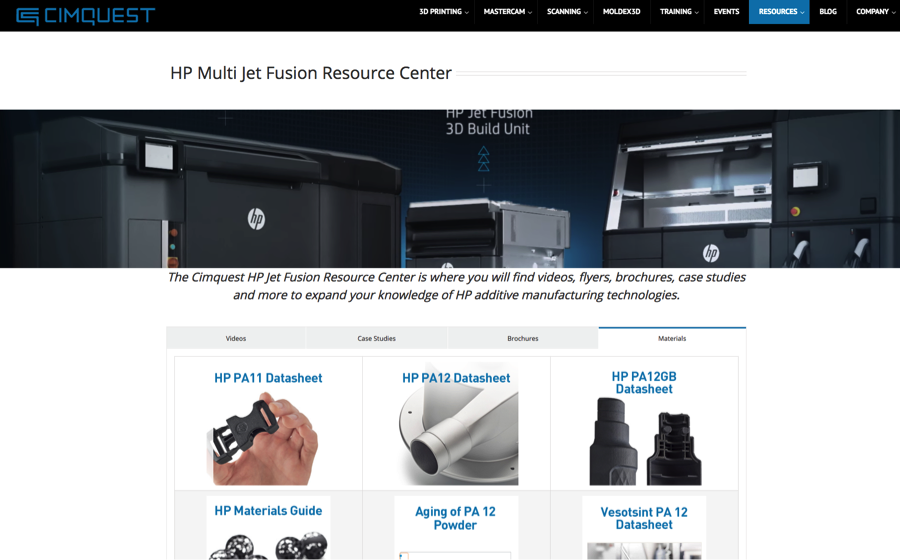

New HP Resource Center Added to Website

We recently added a brand new section to our Cimquest website – the HP Multi Jet Fusion Resource Center. Here you will find a variety of resources to help you learn more about the HP products. From videos and case studies to product brochures and material data sheets, everything you need to further your knowledge of the HP Multi Jet Fusion 3D printers is right at your fingertips. Please click the button below to be taken directly to the Resource Center where you can poke around to discover what’s there. Visit Resource Center