Introducing Castable Wax Resin for Sharp Detail and Clean Casting

Castable Wax Resin, the newest addition to the Formlabs library of Jewelry Resins for 3D printing, is now shipping. This wax-filled material is designed for reliable direct investment casting with zero ash content and clean burnout. Printed parts are suitable for both custom try-ons and final production. It combines sharp accuracy, smooth surface finish, and high green strength, making it our best all-around material for direct investment casting. The way jewelers work is changing and castable photopolymer resins are leading the way. From independent designers concepting and prototyping in their studios, to casting houses increasing capacity and diversifying their offerings, digital fabrication techniques are increasingly key to growing a successful jewelry business. Capable 3D printing materials like Castable Wax Resin are helping jewelry designers and manufacturers scale their production in-house. Highly capable equipment and materials help designers and manufacturers free up time that would be spent making or preparing pieces by hand. With affordable, intuitive desktop 3D printing options like the Form 2, high quality 3D printing is increasingly accessible and scalable for jewelers at all levels. For more information on the Formlabs 3D printers, please click the button below. More info

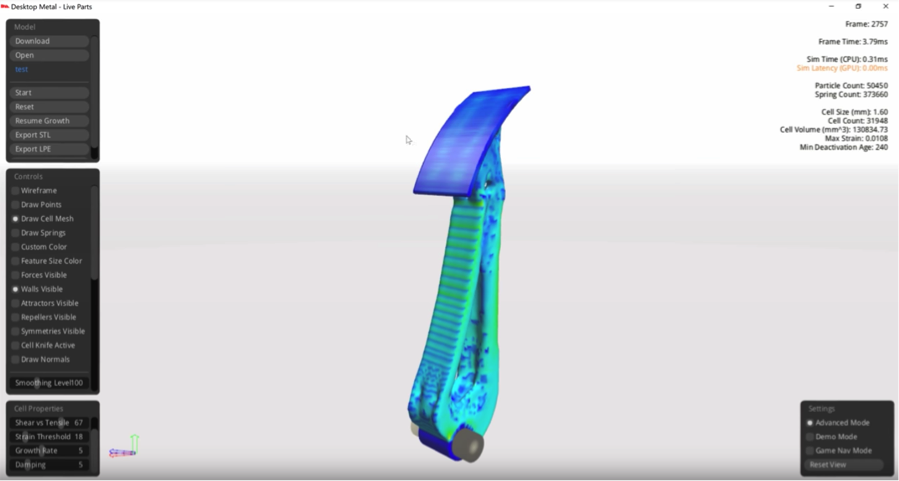

What’s New in Live Parts v.1.3

Desktop Metal has created a nice video that will walk you through the new B-rep geometry import/export functionality in Live Parts™ v1.3. This new version was released in June and this video below will give you a great preview of the technology. For more information on Desktop Metal products, please click the button below. More Info

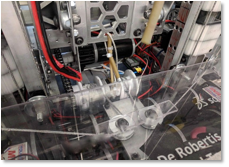

Rize Helps FRC Team Soar to New Heights

Rze Pulley Maximizes Efficiency and Performance FRC Team 1257 had a new competition, or “game,” to play in this year called FIRST Power Up, which entailed building robots that placed boxes on scales in competitive events vs. other FRC teams. The team designed and a printed functional pulley with an integrated sprocket. The pulley/sprocket part was printed in one piece on a Rize™ One 3D printer to reduce the number of parts and minimize part assembly required. The part is operated with a cable. The chain turns the sprocket that is built into the drum of the pulley. Students wind and unwind the assembly to lift and lower the robot’s elevator that holds the boxes. “We chose the Rize One 3D printer to print the part due to Rize’s isotropic part strength and ink marking capability,” said Jackie Gerstein, a technology teacher at UCMHS. “Labeling was printed directly onto the end of the sprocket part to indicate which chain the students need to use to use with that sprocket. This avoided any confusion and potential malfunction.” Rize Pulley Lifts 18 inches to Over 6 Feet in 3 Seconds Using the Rize 3D printed pulley/sprocket part, FRC Team 1257’s robot successfully collected 4 [...]

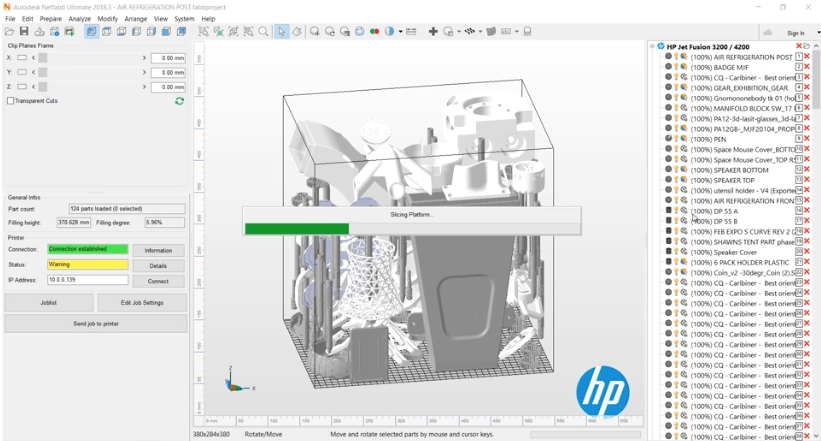

Netfabb HP Workflow

We are very excited to announce that Cimquest is now a reseller for Autodesk Netfabb. Netfabb is Additive Manufacturing software that connects directly to many AM systems to remove the middle step of preparing your build in another program. Today we are going to cover how to use Autodesk Netfabb Premium to repair, prepare, and send your build to the HP JF 4200. There are three tiers of Netfabb : Standard, Premium and Ultimate. In order to connect to the HP JF 4200 workspace Premium or Ultimate is required. In this example, we are using the latest version, 2018.3 and with this version, you are able to drag and drop files into the program. These files are STL’s, 3MF’s and native CAD files, and since Netfabb has a CAD importer built in you do not need to purchase any specific file types. You will notice a dialogue box appears with information on each part and most important the green check mark and for one part the exclamation mark. This shows us if there are any issues with the file, there might be holes in the shell, flipped triangles, or a number of other issues that could cause issues if we tried to print [...]

Custom 3D Printed Orthosis Helps Child Walk

Father Helps Son With Cerebral Palsy Walk With Custom 3D Printed Orthosis Seven years ago, Matej’s and Mateja’s son Nik was born one month prematurely. Due to difficulties during childbirth, he suffered severe brain damage that led to cerebral palsy. Despite the grim initial outlook, Nik was tremendously motivated to be mobile, but the symptoms of his condition prevented him from standing or walking on his own. Matej set out with a simple goal: to enable Nik to walk. Months of research and development followed, resulting in a custom-made, 3D printed orthosis that provides support and correction exactly where Nik needs them, which finally helped him take his first steps independently. Inspired by the immediate improvement, the young parents teamed up with experts and set out on a bigger mission to help improve the quality of life of other children and change the status quo in the healthcare industry by offering truly custom, patient-matched orthotics. Watch the full story below. For more information on Formlabs printers, please click the button below. More info

Hot-swappable Media Cartridges from Desktop Metal

Safe-to-handle, hot-swappable media cartridges have a push-to-release design for easy loading/unloading, while RFID-enabled supply monitoring prevents cross-contamination and ensures you never run out of material mid-print. In this video, Matt Barbati (Technical Trainer at Desktop Metal), gives an overview of the cartridge design and how it supports a seamless workflow for in-house metal 3D printing. Learn more by watching the video below.