Welcome to the Cimquest Blog!

Check here often to find Cimquest, Mastercam and 3D Printing happenings, product offerings and update info along with general Industry trends and breaking news.

March 2021

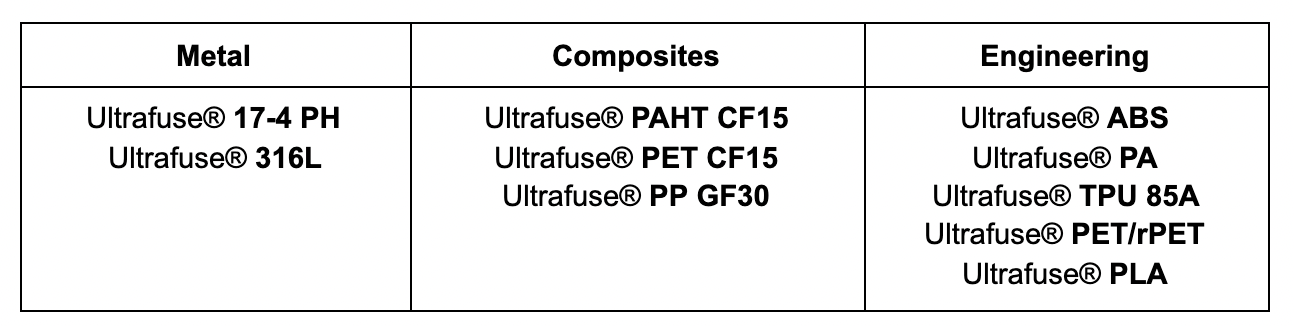

BASF Ultrafuse Metal filaments

We are excited to announce our partnership with Forward AM who provides superior materials and solutions with the goal of leading innovation in Additive Manufacturing. With their direct access to the full spectrum of BASF’s materials know-how and their extensive end-to-end services portfolio, they meet their customers’ highest requirements.

A lot of companies have expressed interest in exploring metal 3D printing […]

Cimquest Used Demo Equipment Annual Sale

We are selling a few of our demo 3D printers. If you are in the market for a 3D printer and are looking for a good deal, please see below for the machines currently available.

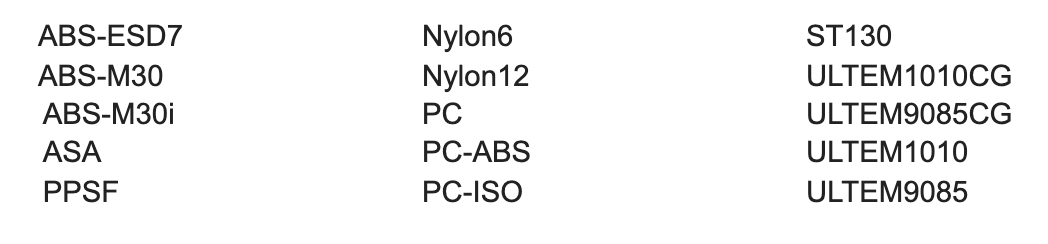

Fortus 900mc Gen2 (Stratasys) – $229,000 (OBO)

FDM Technology

36” x 24” x 36” Build Envelope

Capable of running these materials.

HP Jet Fusion 5200 (20% Discount)

Introducing Shining 3D Freescan UE X7 and X11

Two brand new Shining 3D Freescan scanners called the UE X7 and UE X11 offer a new threshold for high precision scanning combined with a lighter design and enhanced functionality.

The enhanced software can import scans into Control X with a single mouse click, completely streamlining the scan-based inspection process. Accuracy for both the UE X7 and UE X11 is an incredible +/-20 microns (+/-.00078”) with an excellent volumetric accuracy of 20 microns + 40 microns/meter […]

Maximum Material Condition

Why would one want to use a Maximum Material Condition for a true positional callout for clearance holes?

Maximum Material Condition or MMC in GD&T is added to the GD&T symbol. The symbol is shown below.

In this example, we have a .137 diameter clearance hole that is defined as .137 Rad +/-.010”. Let’s assume the hole is manufactured (drilled) and inspected and it comes out as […]

February 2021

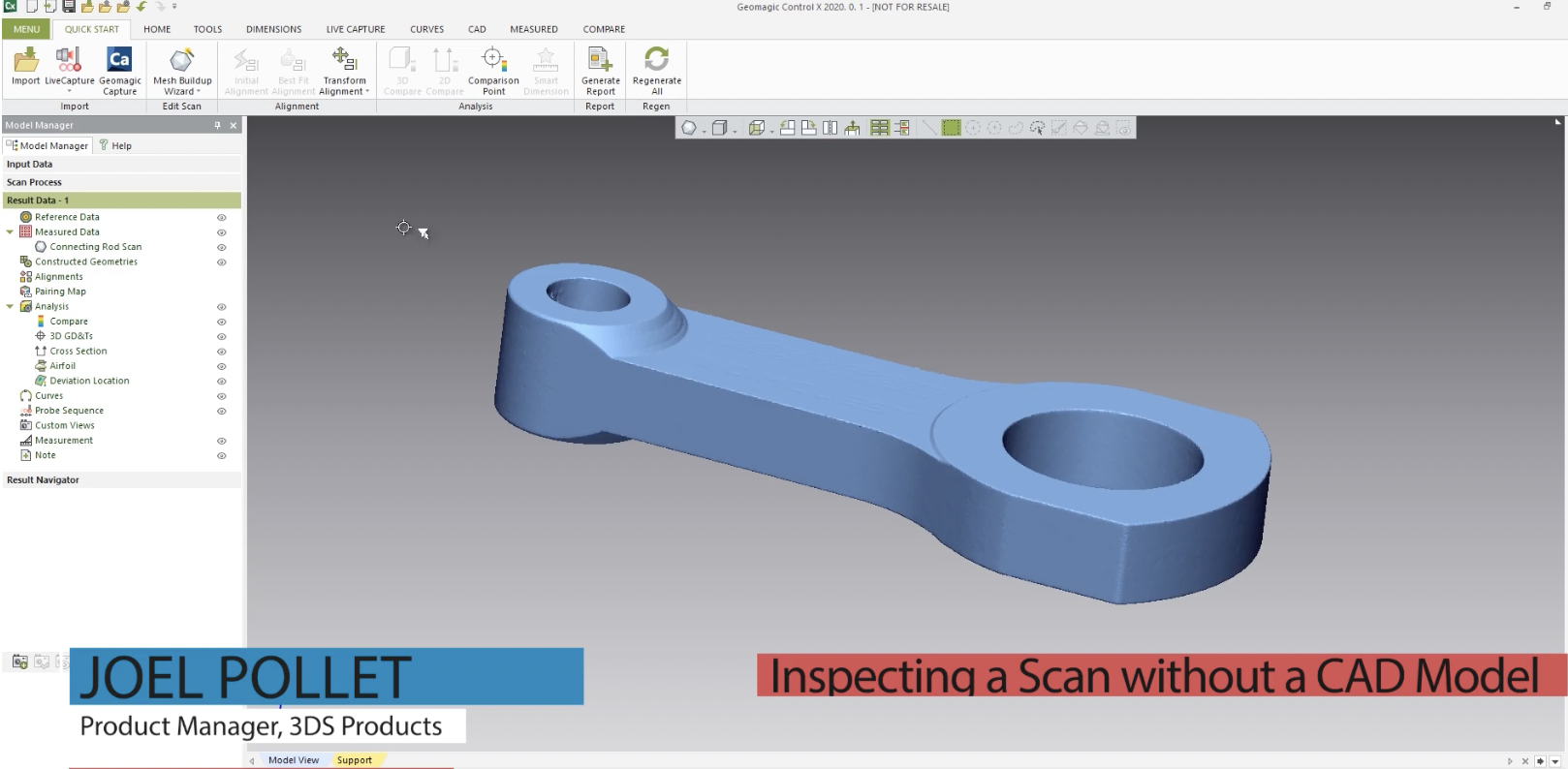

How to Inspect a Scan Without a CAD Model

When using Control X for inspection, you are usually comparing one scan file to another scan file, or a scan file to a nominal CAD file. But sometimes you may have the need to inspect or measure a one-off part without a CAD file to compare it to. This blog post will explain how to take an isolated 3D scan in Control X and take measurements […]

Creating a Water-Tight Model from CAT scan

This blog post will show you an advanced method to clean up internal portions of a CAT scan with the goal of creating a water-tight model. When processing CAT scan data the biggest challenge is cleaning up the geometry. Typically, the internal geometry of a CAT scan contains disconnected poly-faces, which makes it difficult to select and delete only the unwanted geometry. A good example of this is a CAT scan of a bone, as […]