Move Between Milling and Turning Operations With Confidence and Ease

Mastercam Lathe gives you a set of tools that streamline your entire process. From accepting any CAD file to Dynamic roughing and precision finishing, Mastercam Lathe gives you a variety of techniques to turn all of your parts exactly as you need them.

Efficient Programming, Designed for Modern Manufacturing

Basic and Advanced Tools

Mastercam Lathe delivers a set of basic and advanced programming tools, with greatly expanded options when paired with Mastercam Mill. Easy rough, finish, thread, groove, bore, and drill routines combine with C/Y-axis machining to cut any job. Dependable toolpath verification ensures your parts are done right the first time.

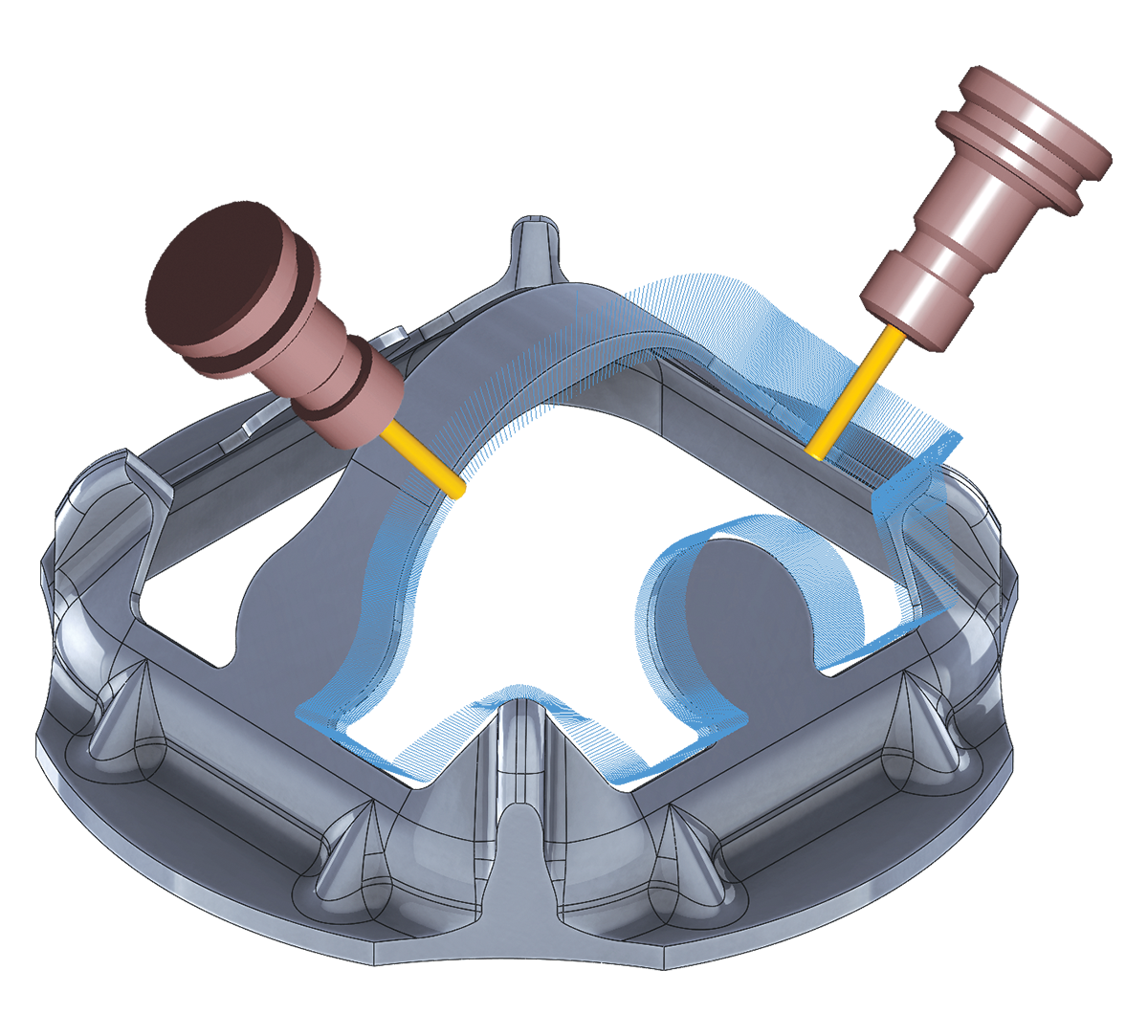

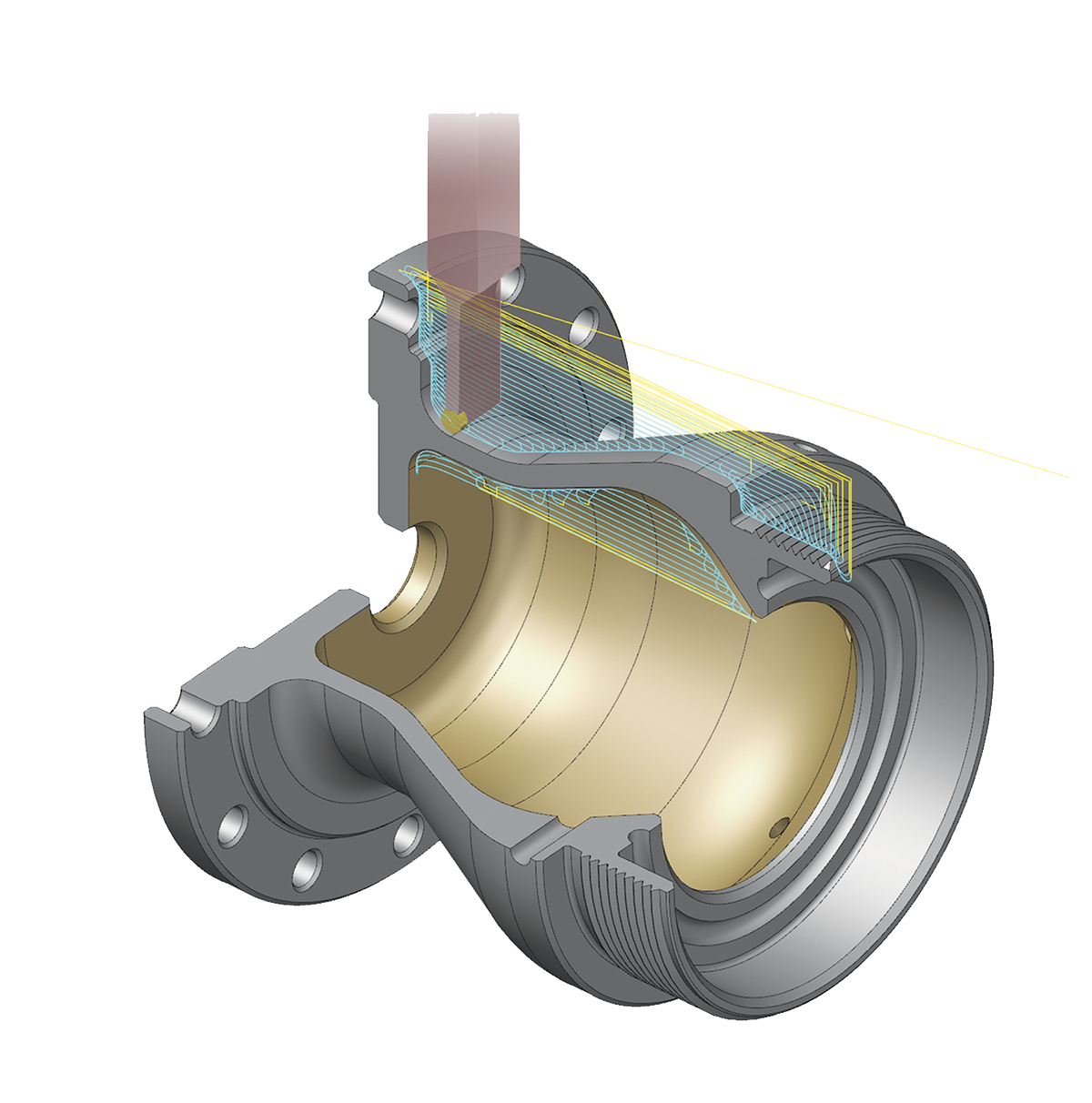

A New Way To Turn

Partnered with Sandvik Coromant

Partnering with Sandvik Coromant, Mastercam delivers automated toolpaths for the groundbreaking new PrimeTurning™ method and CoroTurn® Prime tools. Mastercam’s new toolpath strategy takes full advantage of CoroTurn Prime tool’s unique properties, allowing you to perform turning operations in all directions, resulting in unprecedented productivity gains.

Key Turning Features

Some Key Features of Mastercam Lathe

- Quick Toolpaths let you program in a few clicks.

- Intelligent ID and OD roughing.

- Dynamic Motion roughing extends insert life.

- Rough parts in sections or over the entire model.

- Fast facing including roughing and finishing.

- Grooving with multiple depth cuts, including peck motion and full-radius plunge turning.

- Complete and easy threading.

- Easily control chip breaks on stringy material.

- Automatic gouge checking on the tool’s front and back.

- Chuck, part, steady rest, and tailstock detection.

- Open, quickly align, and directly machine a solid model.

- Quick-turned profiles for uniform and non-uniform parts.

- Full milling support available for machines with live tooling for C- and Y- axes.