When manufacturers are looking for a powerful suite of time- and money-saving solutions, they can turn to Moldplus SA for help in reducing the time required to prepare parts, molds, or tools. Founded in 1993, it was the first company to develop integrated add-on products uniquely designed to complement the CAD tools provided by Mastercam.

The initiative to develop the successful Mastercam C-Hook SDK allowed Moldplus to create advanced CAD tools for mold creation and surface manipulation. Later, their advanced CAD and 5-axis path generation tools were developed due to market demand in Europe, Asia, and North America.

Headquartered in Switzerland, the company’s offerings function exclusively with Mastercam Design, Mill, Lathe, Wire, and Router products. Used in industries such as aerospace, automotive, racing, medical, and more, Moldplus strives to get its customers’ designs completed and manufactured faster using their software solutions.

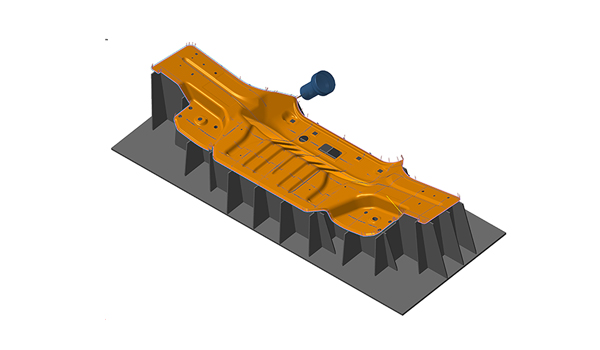

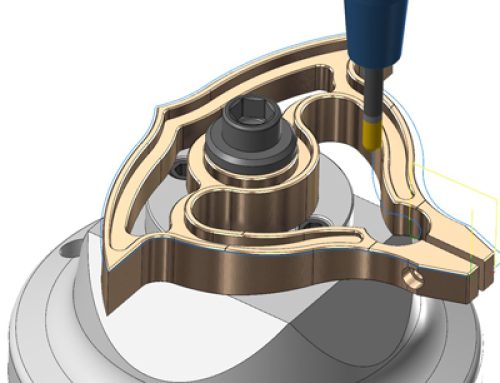

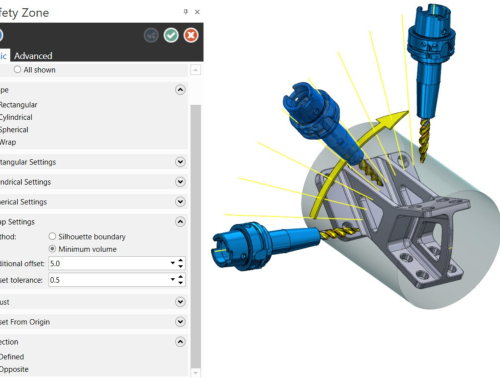

These solutions include tools for preparing parts for manufacturing. “Moldplus provides the user with numerous surface extension functions and surface manipulation tools such as trimming and un-trimming. Our powerful mold preparation tool (core/cavity separation) that is still unique more than 25 years after its initial development, drove many Mastercam sales in the 90s,” said Anbu Lingappan, Business Development Manager, Moldplus.

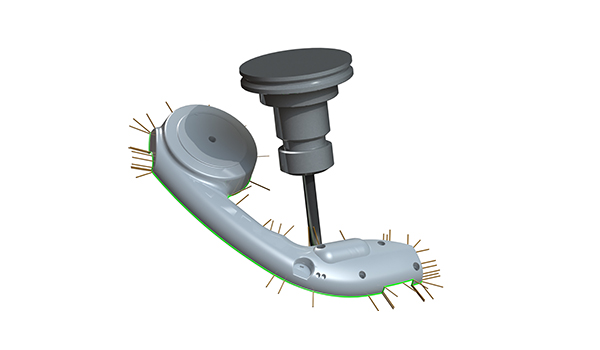

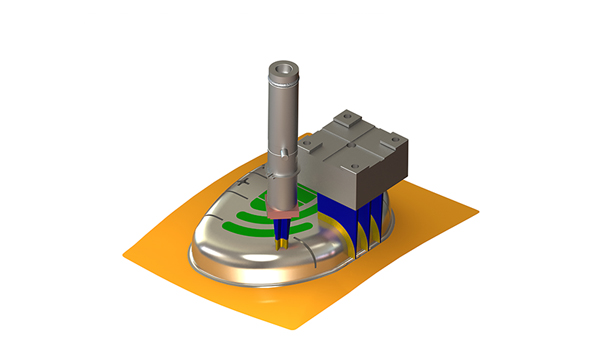

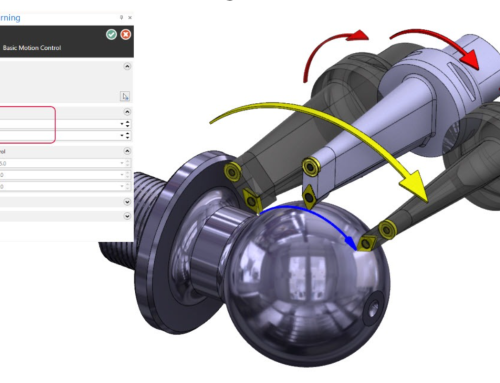

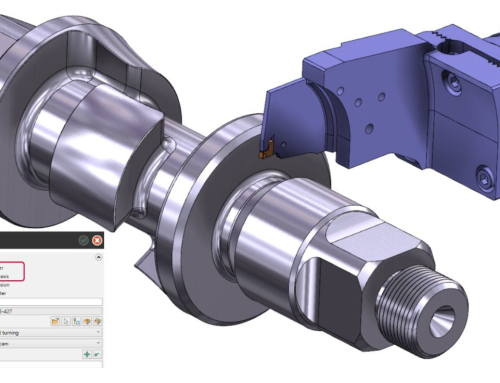

Another product line that has been widely used is the one-click 5-axis curve and drill path creation tools. It provides easy-to-use control for manipulating all the path parameters including full interactive editing of the path’s point positions and vectors at any time.

“Additionally, Moldplus produced the first direct CATIA translator available for Mastercam in 1997 and continued developing a complete suite of CAD import tools from a wide range of CAD systems,” Lingappan said. “Moldplus CAD import products include CAD tree details, manufacturing notes, MBD data, and more. They are industry unique due to their features and benefits offered to the Mastercam end-user who wants to manufacture parts quickly and without the need for CAD drawings.”

These tools are developed to function seamlessly in Mastercam and provide major time savings to its customers. These radically reduce the processing time required to prepare parts for manufacturing. This combination of functionality and reduced processing time helps customers optimize their manufacturing.

“What would previously take hours or days of manual preparation can be done automatically in minutes using Moldplus,” said Lingappan.

Mastercam users have begun to rely on these products to aid in their productivity and also save time and money. For example, 5-axis edge or contour machining is easier in Mastercam when taking advantage of Moldplus’ offerings. They can be more efficient when doing 5-axis milling, 5-axis laser cutting, and 5-axis routing. Customers can even take advantage of advanced robotic trimming solutions.

MoldPlus has a deep-rooted connection with Mastercam, and they look to their future development by listening to their end-users requests. Lingappan explained: “We are continually creating new products and improving our existing tools, features, and CAD interfaces.”

Please click below to request more information about Moldplus.

Leave A Comment