Mastercam X9 Mill offers some new 3D enhancements that are sure to make your 3D work faster and easier. Surface High Speed Hybrid now supports dedicated flat processing, making Hybrid even more intelligent and efficient. Flat processing supports an optional flat stepover, allowing bull nose tools to be programmed with greater efficiency. You can select Flats Only which turns Hybrid into a powerful flat machining option. Hybrid can be programmed to ignore flats as well, allowing you to come back and machine the flats later with a different tool if desired. Create streamlined motion with full coverage by setting Hybrid to include flats, and program an efficient stepover for your bull nose tool to run on the flat areas of your model.

Mastercam X9 introduces new containment boundary options for better control over your tool tip and actual tool contact point. A new containment page has been added to all surface high speed toolpaths.

Surface High Speed Finishing toolpaths now support two ways to treat your containment boundaries for more control over your motion. Select the tool tip to run the center of your tool as the comp point for all containment boundaries as you have always done. In X9, you can select the Contact point of your tool as the comp point to run on your containment boundaries. This new option ensures more material removal while simplifying your programming efforts.

The efficiency of the 3D HST Rest Roughing Linking has been improved. X9 linking moves are closer to your model, eliminating costly excessive air motion when rest roughing against irregular stock shapes.

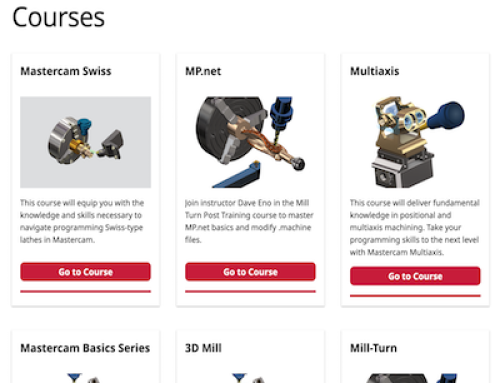

Contact us today for more information or to upgrade to Mastercam X9.

Leave A Comment