What are the benefits of CNC milling over manual milling?

Milling is a manufacturing process in which a part is made by the removal of material around it, specifically by advancing a cutting tool into stock material to cut away the excess. In the vast majority of milling applications, the cutting tool rotates at incredibly fast speeds. It can be used to shave parts down, drill or tap holes, and more. Milling is one of the most commonly used processes in the subtractive manufacturing family.

The main difference between manual milling and CNC milling is how the machine’s motion is directed. Manual machines are controlled by human operators, and CNC machines are controlled by computer programs.

What is manual milling?

Manual milling is the predecessor of CNC milling, but it still has its place in some machining shops. When a machinist operates a manual machine, they do so by controlling the cutter or workpiece entirely themselves. Most often, this means rotating the X- or Y-axis feed handles to directly move the material as the cutting tool is held stationary and spins at a set height.

If you remember how to use an Etch-a-Sketch, you have a rough idea of how this works. The operator must be sure to maintain a smooth, steady motion so as to keep chip thickness uniform.

Manual milling is better when the potential programming time for a part would outweigh its machining time. This can often happen with low-volume runs or with repairs to singular parts. Rather than spend two hours programming a part that takes 15 minutes to fix or even produce, a skilled manual machinist would simply cut the part themselves.

Manual milling loses efficacy when parts require extremely tight tolerances that only computer-controlled machines can produce, when part geometries become too complex for the average manual machinist to fabricate, and when hundreds or thousands of a single part are being made at once.

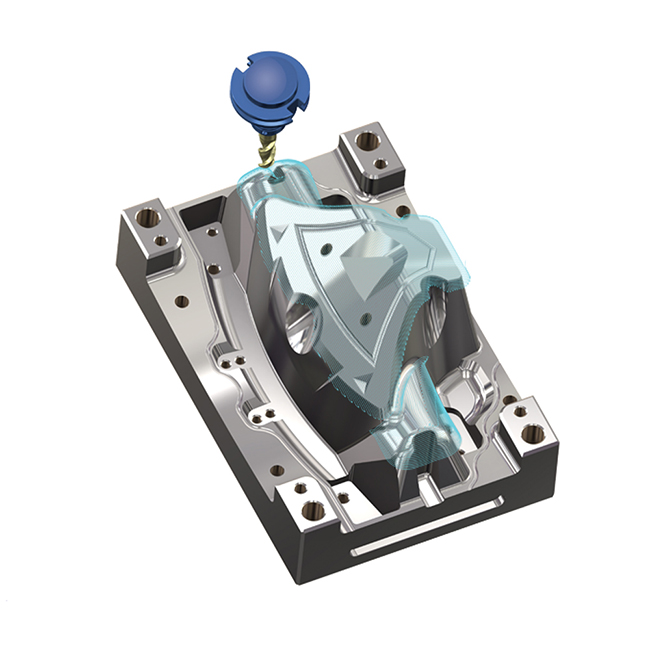

What is CNC milling?

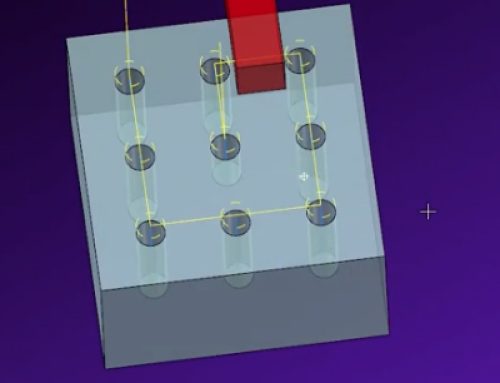

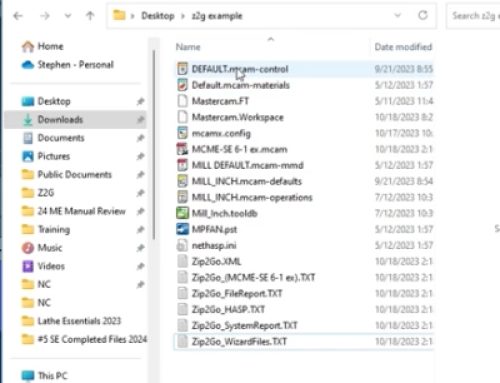

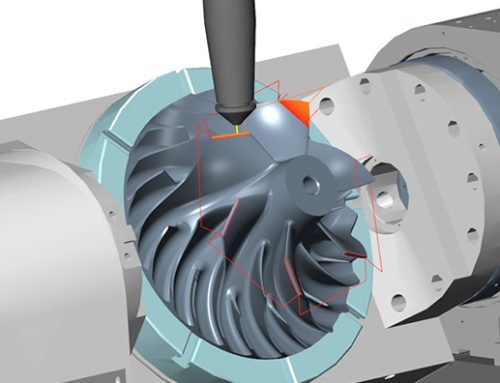

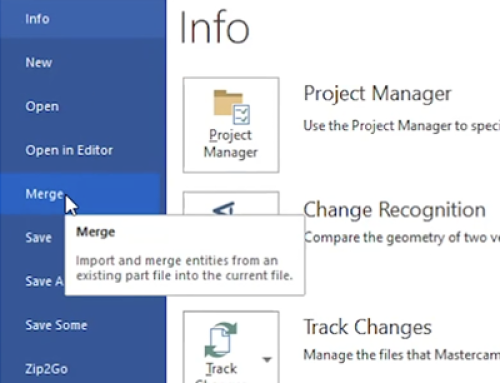

CNC milling is computer numerical control milling, which means that the machine’s motion is directed by a prewritten program. Most often, this code is written by CAM (computer-aided manufacturing) software. CAM systems are designed to interpret a 3D CAD (computer-aided design) model of the part in question, assign toolpaths to it with the aid of a human programmer, optimize those toolpaths to achieve the fastest and most efficient cutting motion, and then output those directions as code that a CNC machine can understand. Once the code is uploaded and the workpiece is fixed in the machine, the operator can start the machine and leave it unattended until a new set-up is required.

For most milling applications, CNC milling is the better option. It has the advantages of delivering tighter, machine-defined tolerances, of more easily machining complicated shapes, and of running parts with minimal human oversight.

CNC milling is better for high-volume batches where programming takes up the minority of the production process and for higher quality parts, both of which are common for larger, international manufacturing corporations. For more information on the complete line of Mastercam CAD/CAM systems, please click below.

Leave A Comment