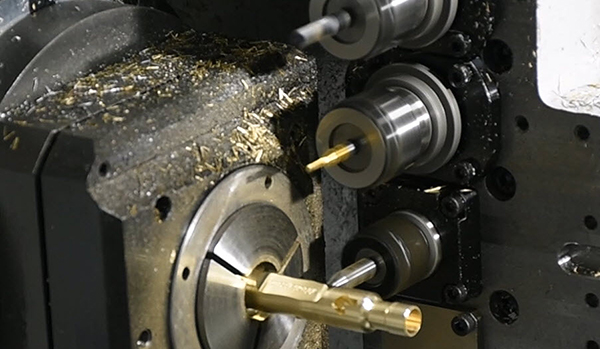

If you are using a lathe to machine a part with a length to diameter ratio that exceeds 3:1, you may be wasting time and money. Luckily, switching from Mastercam Lathe to Mastercam Swiss Solution is quick and simple.

Virtually everything is the same as using Mastercam Lathe when programming a part for a Swiss machine. The Mastercam interface has not changed at all, and you use the same tools inside of Lathe to generate code for a Swiss machine. If you can program a part in Lathe, you have essentially already programmed it for Swiss. The minor differences lie in Custom Parameters, Miscellaneous values, and pick-off and cut-off (POCO) operations.

These differences come into play with machines that have variable options, like the use of high-pressure coolant. This will be different with every machine brand. For example, a Star maching programs differently than a Tsugami, which programs differently than a Citizen. Fortunately, the programmer can easily handle these variables within Custom Parameters and Miscellaneous values.

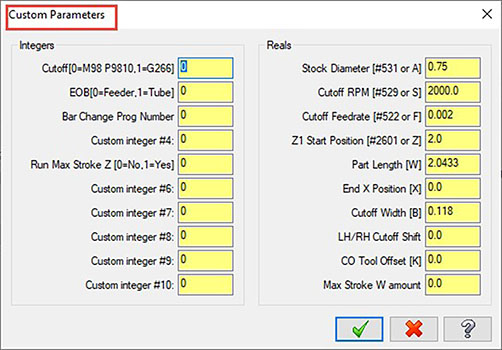

Custom Parameters and Miscellaneous Values look like this in Mastercam:

Using both of these settings allows you to create special switches or options so that you get specific NC code output from the post. Mastercam and the post work together to make this happen.

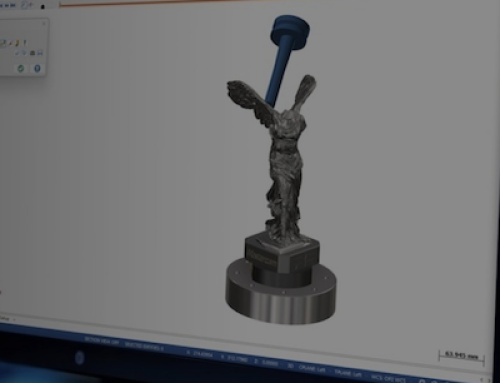

All you need to do to reprogram a part for a lathe to a Swiss machine is load a new machine data file, load a new post, change tool numbers if necessary, and possibly rearrange some operations. This last task is a result of how the stock and tool move in relation to each other in lathe machines versus Swiss machines.

In a Swiss machine, the stock moves in the Z-axis to a stationary tool, whereas the stock in a lathe is stationary while the tool moves into it. For example, a 6-inch-long part with holes and milled flats on the side would require the programmer to rearrange operations. In a lathe, you can turn that whole part from start to finish and then start your crosswork operations. In a Swiss machine, because the stock moves in and out of a guide bushing, you are limited to how much material you can turn back before you start losing support. On a fairly complex part, these changes would take about 15 minutes.

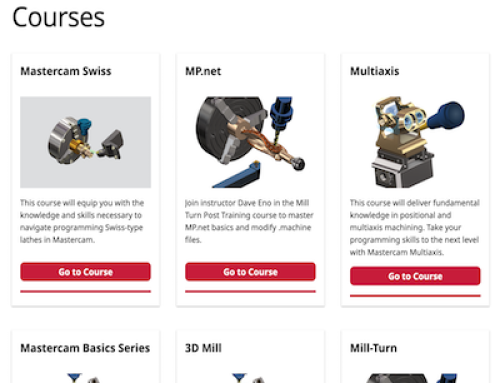

To learn more about the Mastercam products, please click the button below.

Leave A Comment