Additive manufacturing and subtractive manufacturing are no longer mutually exclusive. In fact, to truly get the most out of either, it’s best to combine them in hybrid manufacturing. Mastercam’s new Add-on, Mastercam APlus® by CAMufacturing Solutions Inc., does exactly that. This blog will cover what additive and subtractive manufacturing are, what APlus is, and how it can help you in your own shop.

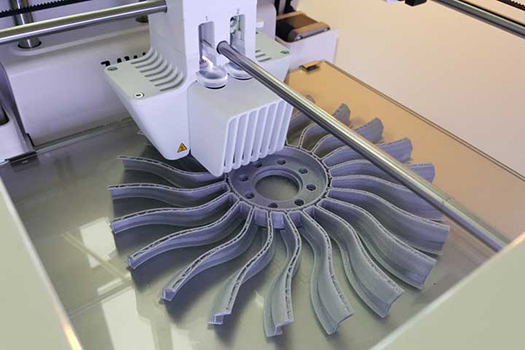

What is additive manufacturing?

Additive manufacturing is exactly what it sounds like – a process by which parts are made by adding material. It is also known as 3D printing. In additive approaches, layers of material are added on top of other materials according to a strict pattern that eventually results in a part. Additive toolpaths are often based off of CAD models and directed by CAM toolpaths, which determine how much material to put where and when. Additive manufacturing most often uses plastic, metal, and ceramic materials.

What is subtractive manufacturing?

Subtractive manufacturing is the opposite of additive. It starts with a whole block of stock material – usually metal, wood, or plastic – and cuts away at it to “reveal” or shape the part within. Milling and routing are subtractive techniques that advance a spinning cutting tool into the workpiece to remove material. Turning is a subtractive technique that spins the workpiece instead of the cutting tool. Like 3D printing, subtractive manufacturing is usually driven off of CAD/CAM programming.

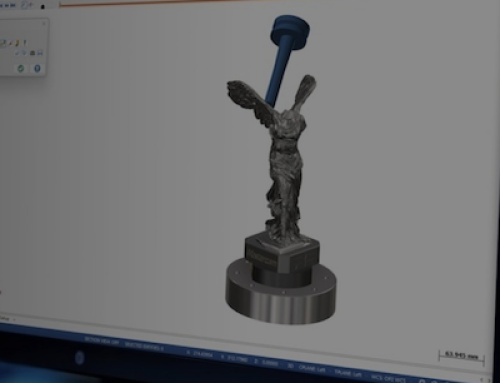

What is Mastercam APlus?

Mastercam APlus is a specialized Add-on designed by CAMufacturing Solutions Inc. to be the perfect key to unlocking hybrid manufacturing for current Mastercam users. The solution works seamlessly with the CAD/CAM software’s Mill, Lathe, and Routing solutions and even runs right in its normal interface. Users can program, backplot, and simulate additive manufacturing toolpaths the same way they do with traditional subtractive toolpaths.

APlus works with Directed Energy Deposition (DED). DED is a relatively complex additive approach most commonly used for metal part repair and to add material to metallic substrates. It is similar to material extrusion in that a nozzle can move in four or five axes, providing it with versatility to build without support materials. Unlike material extrusion, it is more commonly used for metal deposition. Materials are melted by a laser, electron beam, or wire arc outside of the nozzle and on the surface.

How can APlus benefit Mastercam users?

Hybrid manufacturing is the combination of additive and subtractive manufacturing techniques. It gives users the best of both worlds. APlus can revolutionize traditional machining shops in three main ways:

- Producing high-tolerance 3D-printed parts. Additive manufacturing approaches are sometimes speedier and more versatile than their subtractive counterparts, but there is a trade-off. The surface finishes on parts that have solely been 3D printed are subpar. For industries like aerospace and medical, that would make additive manufacturing hopelessly impractical. The only way to make the parts usable is by machining them afterwards to improve their surface finish. By combining additive and subtractive, APlus allows users to program the 3D printing as well as its following finishing milling toolpaths in one place.

- Creating more internally complex parts. APlus makes it possible to switch back and forth between additive and subtractive functions. By alternatively adding and cutting away material during the manufacturing process, users can create incredibly complex internal features on their parts.

- Repairing or modifying old parts. DED is particularly capable at adding material to an existing part. Consider old, worn-down turbine blades. APlus allows users to remove the unusable portions of the blades with subtractive manufacturing and then add back the new tips with additive.

Overall, the product is designed to be a one-stop shop for hybrid manufacturing within Mastercam. It will remove uncertainty and improve efficiency.

Leave A Comment