Jaktool LLC is a customer of ours in Cranbury, NJ. They have a team of young inquisitive engineers that are investing the time to explore the full potential of their manufacturing software and machines to take on the complex jobs no one else wants. Using Mastercam CAD/CAM programming software from CNC Software Inc. (Tolland, CT), Jaktool is able to save setup times and tooling costs, and reduce cycle times, while delivering exceptional customer service to a diverse cross section of industries.

A high-precision prototype technology company, Jaktool specializes in analytical services, manufacturing process development, and prototype manufacturing for the defense, medical, laboratory, and industrial markets, working with just about every type of material from plastics to high-nickel alloys, titanium, and stainless steel. About 50% of their work is for the military—supporting prototype weapon systems and ballistic hardware components for airborne, surface, and sub-surface applications.

Jaktool’s team and president Jeff Kinsberg (center, foreground).

Parts can be as small as 0.040″ (1-mm) rivets for an aerospace application or as large as 18″ (457 mm) in diameter for sub-surface applications. Prototype volumes run from one to 5000 pieces, with the average being 50 pieces. In the machine shop, about 65–70% of their work is turning; the balance is milling. The work is performed on two-axis CNC lathes, five-axis dual-spindle lathes, and three to five-axis mills.

Every one of Jaktool’s 10 mechanical and electrical engineers is capable of bringing the parts from print to final product, according to Ryan Hollywood, manufacturing engineering manager, “This isn’t a typical job shop where we have two programmers and we hand the rest off to machine operators. All of the guys who are making the parts are the same guys programming the parts. Each person has ownership of a part, following it through every manufacturing process—turning, honing, grinding, tapping, and everything else until the part is finished. Because each person wears many hats, including running two machines simultaneously, we need to move product through the shop quickly and efficiently so that everyone can run their jobs,” said Hollywood.

Intern Kevin Zheng is using Mastercam’s Transform function to create planes to cut from for every angle of this perforated liner. Machining was done in one operation yielding a more accurate part.

CNC Software, through its reseller network, has been a valuable resource for training Jaktool employees who are largely self-taught through experience, Mastercam manuals, and forums that they attend. The shop was a beta site for Mastercam 2017 where, through trial and error, employees were able to discover its new powerful programming functions. The first time a new feature was implemented, for example, it took roughly one and a half times what it normally took to program a part. However, by the second try, the team cut about 25% of the cycle time, followed by cutting 25% of the setup time.

Jaktool maintains a strong and rewarding internship program. Based on their strengths, interests, and willingness to put in time, interns are encouraged to go beyond button pushing and finishing tasks. While both play an important role in learning and appreciating manufacturing processes, an intern’s true value as a future engineer is discovered when he becomes a problem-solver. Kevin Zheng, who is an intern and electrical engineering major, is typical. He continually explores different ways to program the toolpaths to push the machines to their maximum capabilities. And it doesn’t hurt that he really likes making chips.

When in the shop, Zheng is dedicated full time to milling operations. He prefers projects that are non-repetitive that challenge him to investigate Mastercam’s many features. When the college senior started his internship, Jaktool was doing four-axis jobs that were ideal for surfacing. When Hollywood turned Zheng loose on the software, they learned more functions, enabling them to take on more complicated jobs using the four-axis machines.

Previously, four-axis positioning was programmed by hand. An early project involved a part design with features that were in a radial pattern that required four-axis machining. Using Mastercam’s Transform feature, Zheng was able to take existing toolpaths and translate, rotate, or mirror them to machine multiple parts (or holes) that were exactly alike. “We could put this part in a vise with four or five different operations, but we wanted to see how we could do it on one operation in the fourth axis. We did it by creating planes to cut from for every angle. More time is spent programming the part, but the end result is a more accurate part because it isn’t refixtured several times,” said Zheng.

Mastercam’s Dynamic Motion technology removes material quickly due to proprietary algorithms in the software that intelligently sense changes in the material, allowing the tool to remain in constant contact with the material with little or no stepovers.

According to Hollywood, Mastercam 2017 makes it easier to transition from their Solidworks design software to Mastercam when the part needs to be programmed from the solid. Further, when a part is designed in Solidworks and the part needs compensating during manufacturing, the part is redrawn in Mastercam.

“This capability is especially helpful when doing jobs for the US Army because of the format in which we receive the orders,” said Hollywood. “When we create a wireframe from their IGES or their solid, we sometimes need to redraw it to optimize toolpaths. For turning and milling, we redraw many parts with the exception of very complicated parts. In that case, an IGES is imported into the CAD/CAM software and coordinates are reset into the correct planes so that the XYZ axes are in the proper location.”

Mastercam’s Dynamic Motion technology is credited with playing a major role in Jaktool’s ability to slash manufacturing time. “When it comes to milling, every single program I write has some Dynamic Motion in it because I found out it is way easier to remove material,” said Zheng. He chooses the material, then a wireframe, a tool, and a stepover, and programs it into the high-speed toolpath, often creating complex geometries and roughing operations at the same time. Dynamic Motion removes material quickly due to proprietary algorithms in the software that intelligently sense changes in the material, allowing the tool to remain in constant contact with the material with little or no stepovers. Because the tool is constantly engaged with the material, there are fewer tool breakages as well.

“I learned how to do stuff without Dynamic and then, when we started using the technology, it cut cycle times in half when it came to roughing repeats. It extended tool life by 20–30%,” said Hollywood. Because Jaktool doesn’t do the same jobs every day, the high speeds possible with Dynamic Motion provide the team with the means to push the machines to their fullest potential while streamlining the entire manufacturing process. For example, the team had a repeat job that called for 910 pieces. They knew that it took 12–13 minutes to run. Recently, they programmed the part using a dual-spindle machine, programming it with a left spindle and a right spindle in Mastercam, then completing the transfer. The cycle time was reduced by 20%. “In the long run, minutes add up to days, so we realized about a week and a half time savings,” said Hollywood.

One of the more difficult jobs Jaktool accepted was for a small tubular shape featuring 120 radial pockets with a thin wall. All of the pockets needed to cut off the axis, putting the milling operation at about an hour per piece. According to Hollywood, no one else would touch the job. The young experienced team quoted 50–60 minutes to complete, due to its unpredictability. About a week prior, Zheng learned how to use the software’s Transform/Rotate feature, enabling him to program seven or eight pockets per row and roughly 24 to 36 angular positions, rather than 120 individual pockets manually.

“I only had to program it once and set to repeat to go in a row, and another repeat to go around the entire part,” said Zheng. “I cut our cycle time down to 15 minutes and didn’t break a single tool during the entire run.” Approximately 200 lb (90 kg) of material was used, according to Hollywood. Set up time was three to four times as long as programming solids, but by using all of the Transform/Rotate features, Jaktool was able to cut the cycle time to 25% of the original quote.

The tight tolerances called for in military specs pose a particular challenge in turning operations. Many jobs are plus or minus one thousandth of an inch tolerance, on parts that can measure from 10 to 12″ (254–305-mm) diameter. Finishing requirements are also stringent. “There is a lot of science behind the parts that we’re making. These aren’t just standard parts with plus or minus five thousandths. We are able to take on a lot of challenges with different parts and, as a team, we’ve grouped together, figured it out, solved problems, and made these parts that other shops would shy away from,” said Hollywood. “The software helps us do that.”

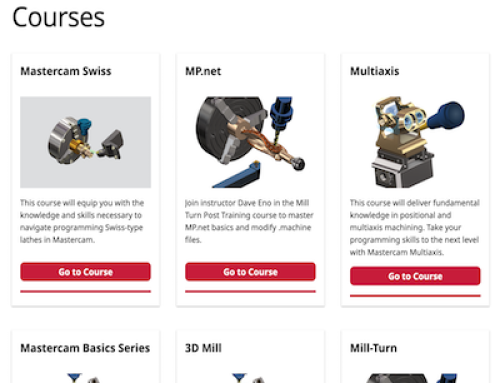

To learn more about our Mastercam products, please click the button below.

[button link=”https://cimquest-inc.com/products/subtractive-manufacturing-products/” color=”default” size=”” stretch=”” type=”” shape=”” target=”_self” title=”” gradient_colors=”|” gradient_hover_colors=”|” accent_color=”” accent_hover_color=”” bevel_color=”” border_width=”1px” icon=”” icon_divider=”yes” icon_position=”left” modal=”” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” alignment=”left” class=”” id=””]More Info[/button]

Leave A Comment