By Joel Pollet, Senior Services Specialist

Historically, machine shops relied on two items from their customer to fulfill a machining order; a CAD model and an inspection drawing. During my 3 ½ decades in our industry, the high-end, integrated CAD/CAM systems have always been able to convey manufacturing information from CAD to CAM or CAD to CAE.

But what about CAD/CAM interfacing, such as Solidworks into Mastercam? These are two completely independent products from independent companies with independent development paths and unrelated requirements. Sharing model geometry is about as far as they go, but times are changing rapidly.

Product Manufacturing Information (PMI) offers a way to convey dimensional information, tolerance information, datum information (where applicable), as well as GD&T information between dissimilar systems. There are higher levels of PMI that also support the transfer of other types of attributes or non-geometric information (part number, manufacturer, etc.).

If the designer of a part can convey all of this information to their machine shop partners as embedded PMI within the CAD model, wouldn’t that make the shop much more efficient by having one less document to manage and also offer a far less ambiguous way to present dimensional information?

Most modern day CAD systems support the creation of PMI in one form or another. It’s only a matter of time until CAM systems and other similar disciplines find a way to utilize the PMI data. While most call their PMI interface, ‘PMI’, some products provide a special name. For instance, Solidworks refers to its implementation of PMI as ‘Dimension Expert’.

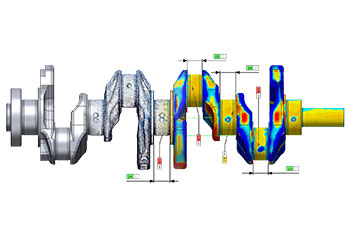

Perhaps products you currently use in your shop already support PMI? The ideal scenario involves CAD to CAM integration for design to machining, or CAD to CAE integration for design into analysis.

For example, Cimquest represents inspection software that supports PMI transfer from many supported CAD systems. There is even a new format for the Step neutral file translator called Step 242 that supports embedded PMI information and is included in the exported file.

PMI offers a way for completely dissimilar systems to ‘integrate’ and share critical manufacturing information and, as mentioned, it’s only a matter of time before it is a widely accepted (and expected) technology in our industry.

Leave A Comment