Desktop Metal’s Bound Metal Deposition technology brings metal 3D printing into the office environment, making low-cost prototyping of metal parts achievable as well as user-friendly and cost-effective.

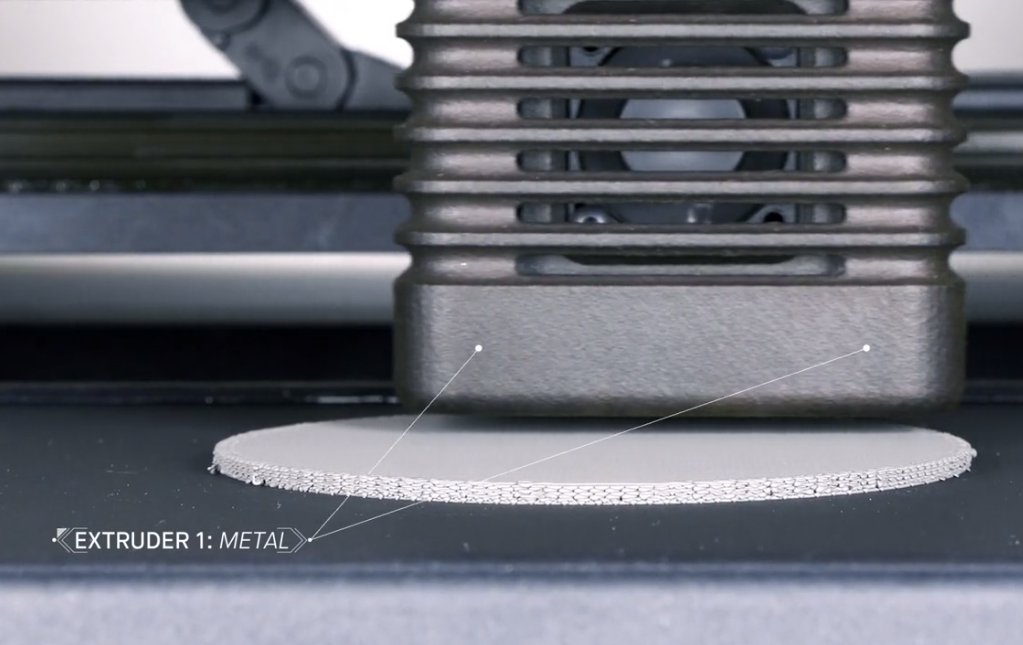

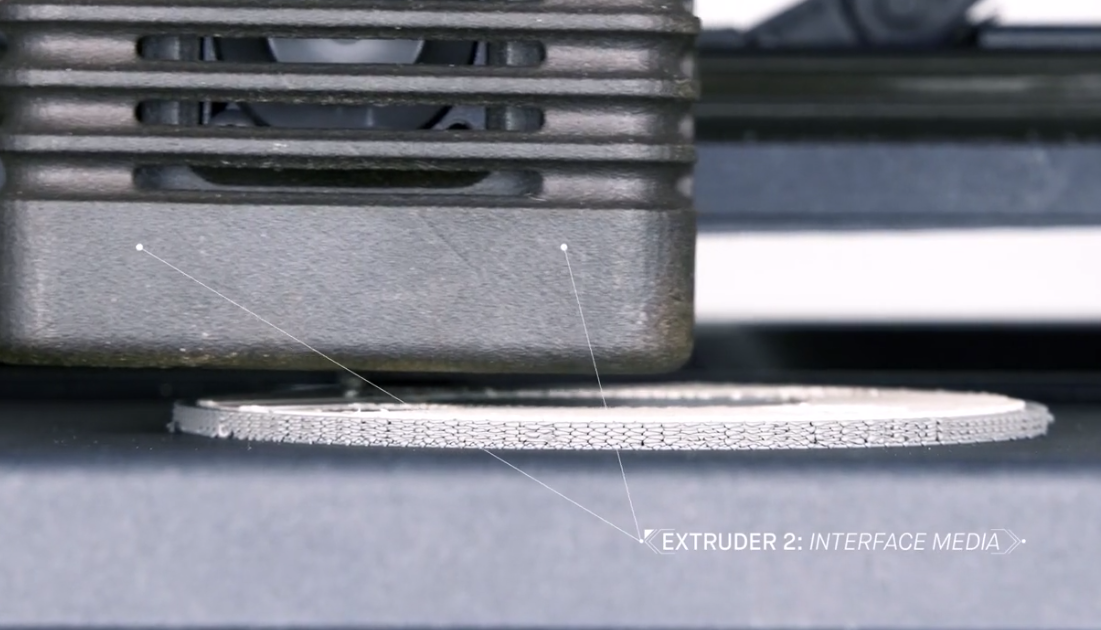

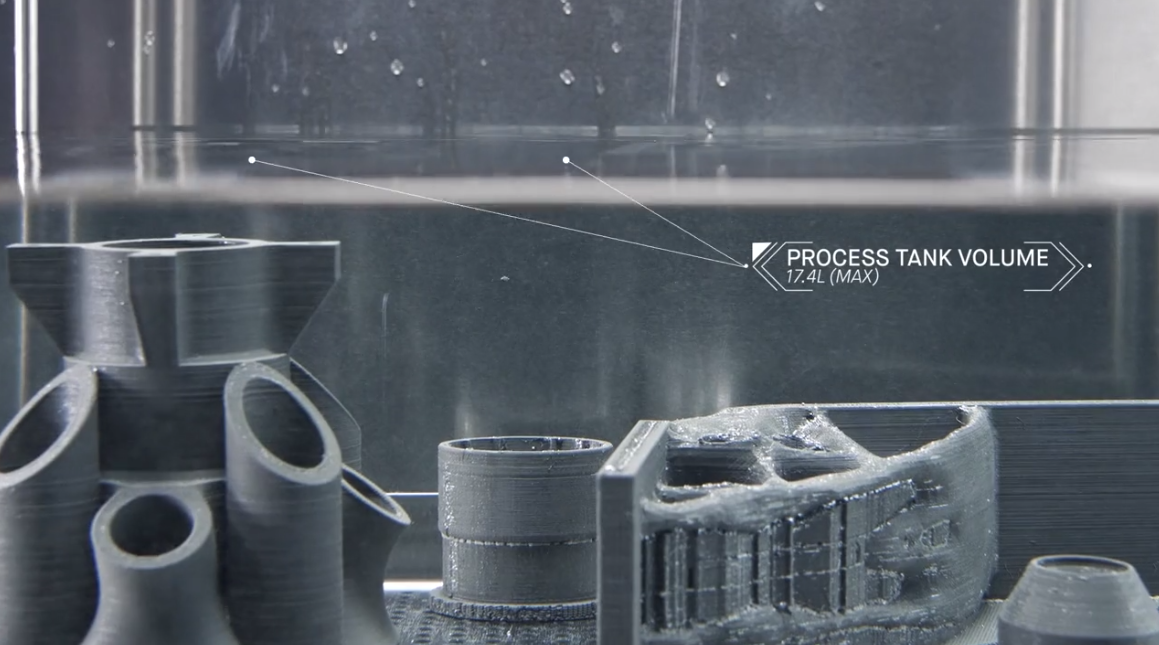

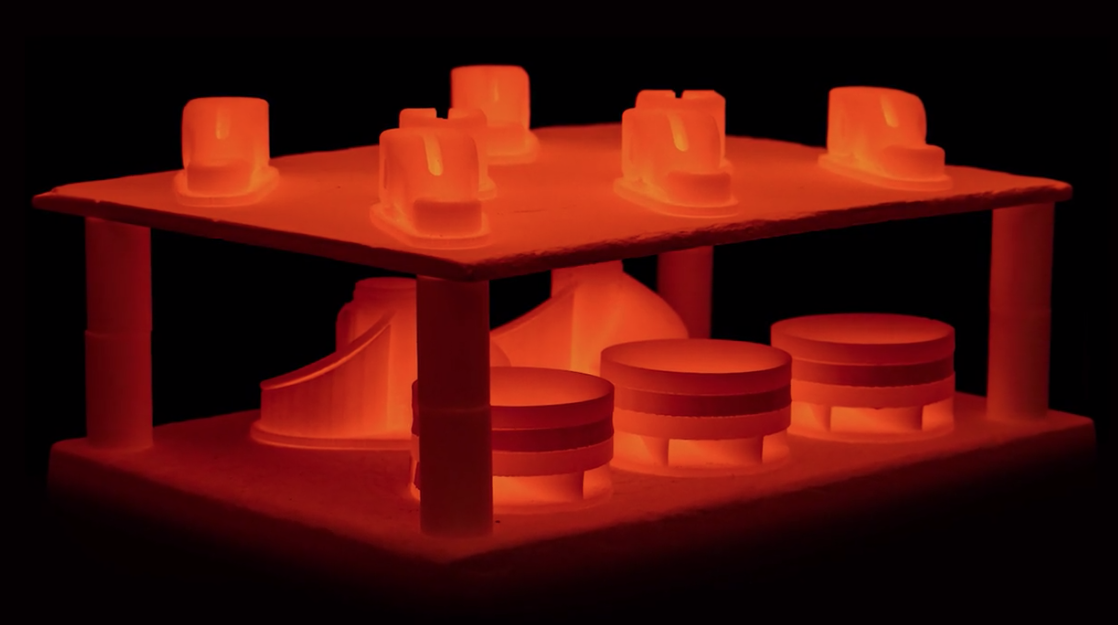

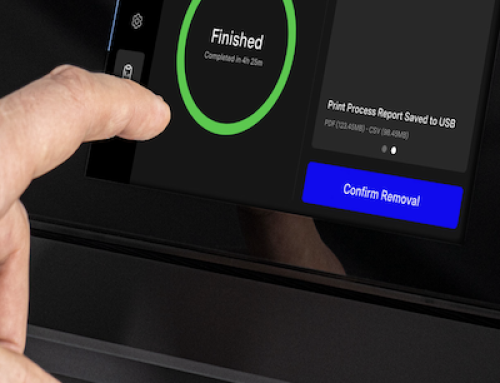

The Studio printer extrudes rods that have metal powder bound within wax and plastic to form the parts. The binders in these parts are then removed through a two-step process of debinding and sintering similar to metal injection molding; also known as MIM.

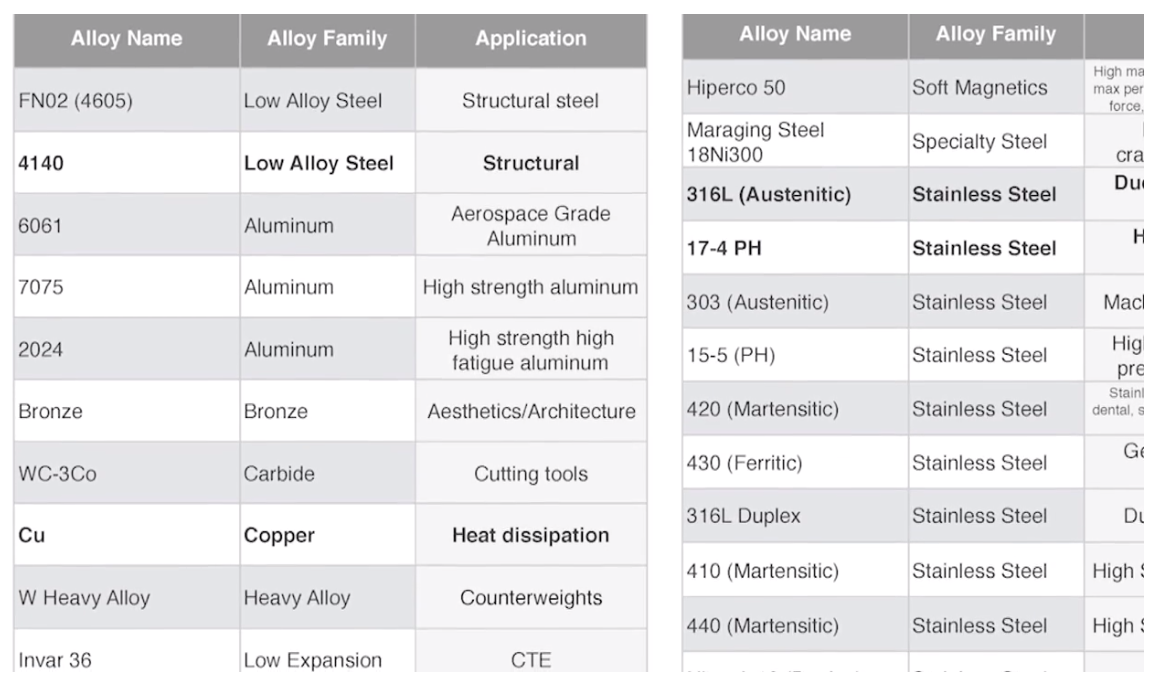

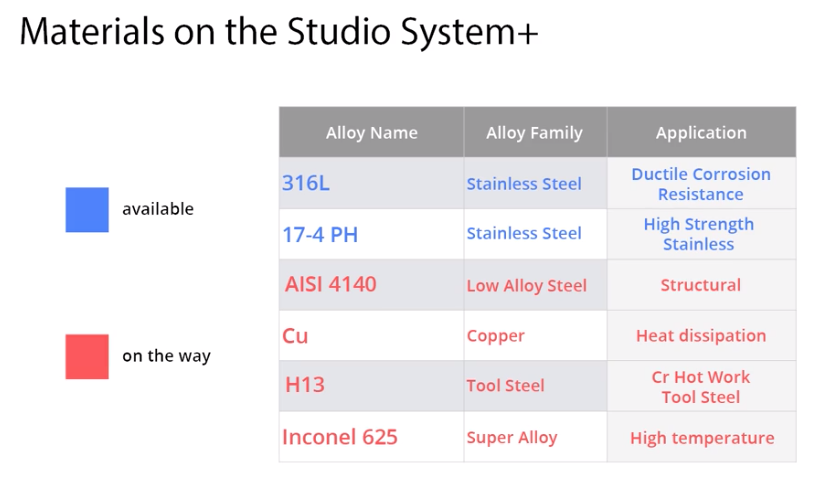

Desktop Metal’s Bound Metal Deposition platform will ultimately have access to a wide range of metals from the MIM industry and there are currently 30 materials in development.

The materials currently available are 17-4 & 316 stainless steels:

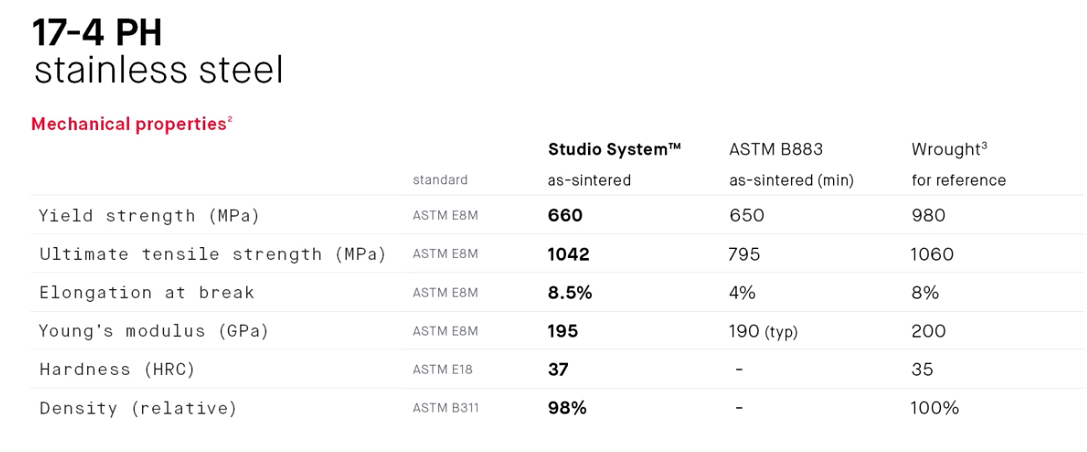

17-4 stainless is characterized by its combination of strength, hardness, and corrosion resistance.

It is ideal for a variety of applications including tooling, molds, and production parts. In its as-sintered state, 17-4’s material properties consistently meet industry standards.

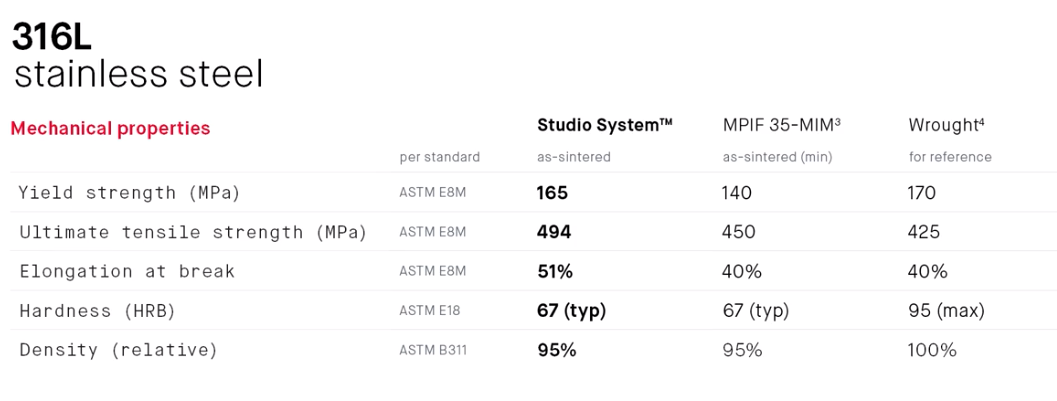

316 stainless was just released and is a fully austenitic steel known for its corrosion resistance and performance at both high and low temperatures. It is well-suited for applications involving chemical processing, saltwater environments, and household or industrial fixtures.

One great example is a Fuel nozzle by John Zink Hamworthy Combustion, used on steam propulsion boilers on liquified natural gas tankers. The nozzle features complex internal channels that optimize particle distribution to render the most effective combustion. These channels are only achievable using additive manufacturing methods, but laser-based technology can be extremely cost-prohibitive.

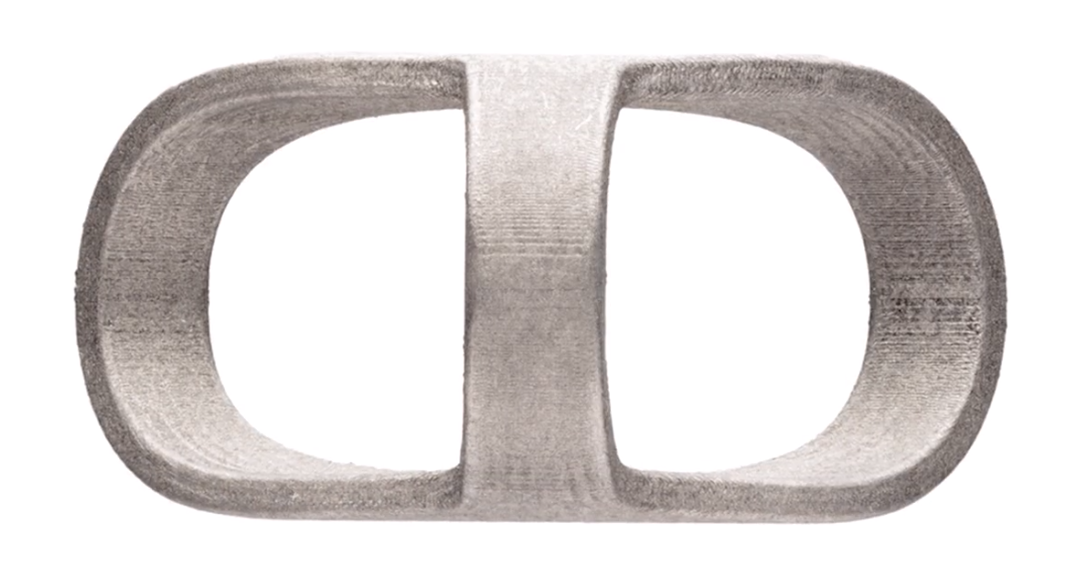

This medical finger splint was also made with 316 due to its increased durability and improved aesthetics when compared with a plastic alternative.

As you can see, the Desktop Metal Studio System allows engineers to develop geometrically complex metal parts in-house at a fraction of the cost of other industrial metal systems. Please be sure to sign up for our 2 Minute Tuesday video series to receive information like this in video form every week. More info at the button below.

Leave A Comment