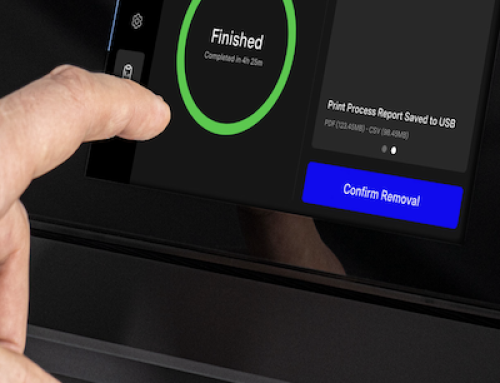

A 3D printed quick changeover insert printed with Multi Jet Fusion for HP’s Sprocket assembly line.

HP has revealed further cost and weight savings within its print and packaging businesses thanks to the internal application of its 3D printing Multi Jet Fusion additive manufacturing technology.

As the company continues to scale its ‘HP on HP’ program, more than 100 components of its Indigo 2020 press portfolio have been manufactured with 3D printing, while a reduction of 5007 parts across 84 different part numbers on its packaging lines has also been recorded. HP on HP was initiated in 2018, with the company first targeting its Multi Jet Fusion hardware, before expanding the application of 3D printing technology across its various other business units.

The recent announcement of HP’s Indigo 2020 portfolio of presses highlighted this implementation of 3D printing, with redesigns of components generating a 90% weight saving, as well as reductions in its carbon footprint, production time and energy, and material consumption. Meanwhile, on the packaging side of the business, the roll-out of 3D printing has helped to achieve $111k within a year.

HP on HP: How the internal use of 3D printing is shaking up one of the world’s biggest plastic supply chains

In Richmond, Virginia, HP America’s Product Completion Center, which packages inkjet supplies for the company’s North and South American customers, says it has over 100 unique part designs across 19 packaging lines. Among the parts on HP’s Sprocket line – a product available in two different sizes – are a quick changeover insert that carries interior components along the line and pusher heads which move those components onto the next phase of assembly. Different sizes of these pusher heads are set to be printed in different colors using HP’s full color 300/500 series to make it easier to differentiate between the two versions, while the changeover insert has parts that can click out and back in.

These kinds of applications are being introduced across a range of the company’s manufacturing plants in a drive that has come from the top-down, with HP’s senior management encouraging its engineers to get creative. The thought process is that enabling creativity can help to achieve significant gains, break corporate inertia and, in turn, support the company’s customers in doing the same.

Talking to TCT last year, HP’s Chief Supply Chain Officer Stuart Pann reckoned 3D printing would ‘bring back the ear of the craftsmen,’ while colleague Scott Schiller said the aim was to see Multi Jet Fusion users replicate their HP on HP program, although ‘there’s no better place to start than home.’

For more information on the HP Jet Fusion technology, please click the button below.

Leave A Comment