reprint from https://www.nanalyze.com/

While Desktop Metal is known for its office-friendly Studio System for prototyping, no doubt much is riding on the success of the Production System, which Desktop Metal claims is the world’s fastest 3D metal printer. The company goes on to say that the Production System is more than four times faster than any binder jet competitor and offers a 100 times speed improvement over any laser-based system – all at up to 20 times less cost than other 3D metal printers. It can churn through 150 metric tons of metal per year.

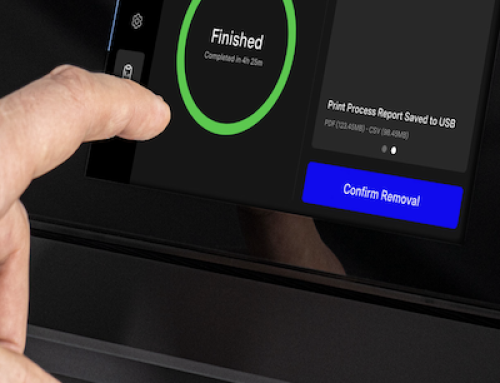

Production Printer. Credit: Desktop Metal

The machine uses two print bars containing more than 32,000 nozzles that work in conjunction with powder spreaders to disperse metal powder and print in a single pass across the build area, jetting up to three billion drops per second. Once the loose powder is removed from the part, it is heated to near the melting point to remove any remaining binder, causing the metal particles to fuse together and the parts to densify in a process known as sintering.

Advantages

One of the real advantages of 3D metal printing is that manufacturers are no longer shackled to the manufacturing method, allowing them to design parts that optimize material and function. Or, as Myerberg puts it,

“You’re making parts that are designed not for their manufacturing method, but more for their application.”

Automotive manufacturers, for instance, can shave serious weight if they can shrink the number of parts required for a vehicle chassis from, say 17, to just one 3D printed piece. Companies like GE are already doing that in aerospace manufacturing using laser-based 3D printing. Electric vehicle manufacturers (see investors list above) could do the same using metal parts that are lighter, stronger, and more compact. And there’s an additional advantage, according to Myerberg, in that metal is infinitely recyclable compared to polymer-based materials, which appeals to his environmental side.

For more information on the Desktop Metal 3D printers, please click the button below.

Leave A Comment